18 Years Factory Extrusion Blow Moulding Process Step By Step - PP/PS Sheet Extrusion Line – JWELL

18 Years Factory Extrusion Blow Moulding Process Step By Step - PP/PS Sheet Extrusion Line – JWELL Detail:

Product Presentation

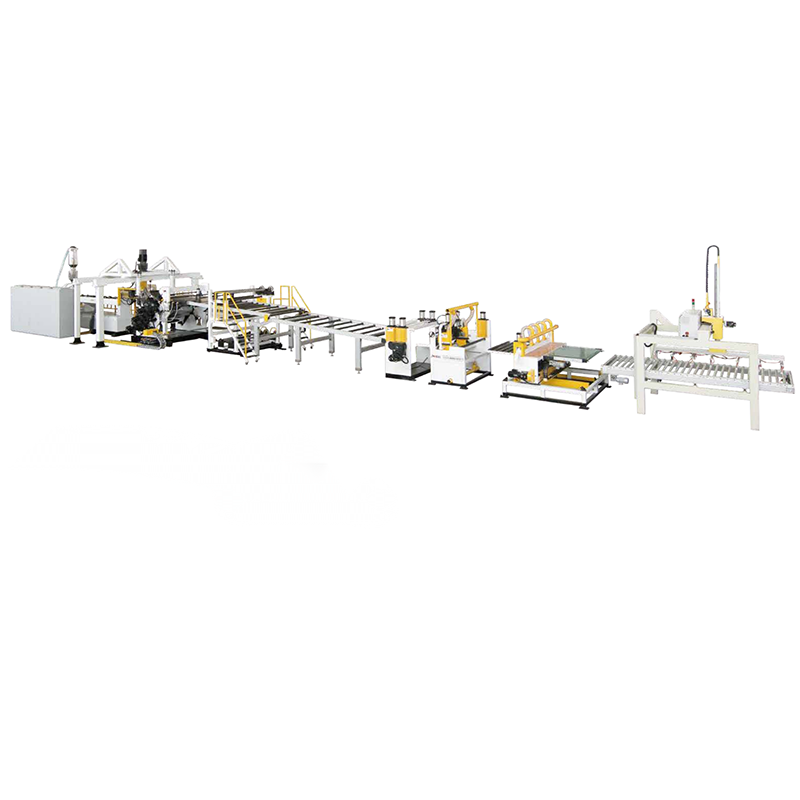

Developed by Jwell company, this line is for producing multi-layer environmental-friendly sheet, which is widely used for vacuum forming, green food container and package, different kinds of food packaging container, such as: salver,bowl, canteen, fruit dish, etc.

Adopting maxim talc percentage in the sheet production, either customer will be able to reduce the cost of the sheet or increase the sheet degration character as well as gaining good physical properties and further processing abilities.

Main technical parameter

| Model | JWS150/120/90-1800 | JWS150/60-1200 | JWS130/60-1000 | JWS120-1000 | JWS100-800 |

| Width | 1500mm | 1000mm | 900mm | 800mm | 600mm |

| Thickness | 0.3-2mm | 0.3-2mm | 0.3-2mm | 0.2-2mm | 0.1-0.8mm |

| Capacity | 1000-1200kg/h | 700-800kg/h | 550-600kg/h | 400-

500kg/h |

300-350kg/h |

Product detail pictures:

Related Product Guide:

With reliable quality process, good reputation and perfect customer service, the series of products produced by our company are exported to many countries and regions for 18 Years Factory Extrusion Blow Moulding Process Step By Step - PP/PS Sheet Extrusion Line – JWELL , The product will supply to all over the world, such as: Jakarta, Ghana, Romania, We welcome customers from all over the world come to discuss business. We supply high quality solutions, reasonable prices and good services. We hope to sincerely build business relationships with customers from at home and abroad, jointly striving for a resplendent tomorrow.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.

Write your message here and send it to us