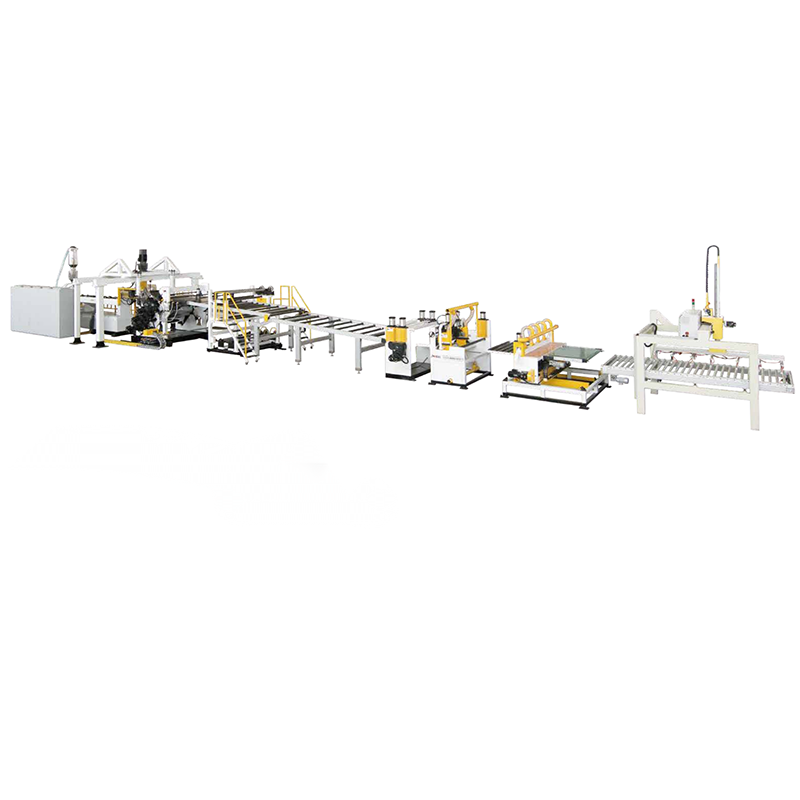

18 Years Factory Extrusion Blow Moulding Process Step By Step - PVC Roofing Extrusion Line – JWELL

18 Years Factory Extrusion Blow Moulding Process Step By Step - PVC Roofing Extrusion Line – JWELL Detail:

PVC corrugated board and Step-Roofing feature and application

● The fire protection performance is remarkable, difficult to burn. Anti-corossion, Acidproof, alkali, radiates quickly, high light- ing, logn life-span.

● Adopt special technology, bears the outdoor atmospheric insolation,the heat insulation performance is good, in the hot summer can provide compares the metal to use a tile more comfortable environment.

● The applicable scope is broad, the workshop, the warehouse, the vehicle shed, the agricultural market fair, the brattice, the wall body, the temporary store, the heat insulation awning and so on are suitable.

Main technical parameter

| Extruder Specificatior | $jz80/ 156&$J251/105 | $JZ80/156&Jw$50/30 | SJ292/188&JWS65/30 |

| Main motor power | 55kw | 55kw | 110kw |

| Products Width | 1140mm | 850mm | 880mm |

| capacity(Max.) | 300-40@kgh | 300-400kg/h | 400-600kgfh |

Product detail pictures:

Related Product Guide:

We'll make every effort and hard work to be superb and excellent, and speed up our steps for standing inside the rank of intercontinental top-grade and high-tech enterprises for 18 Years Factory Extrusion Blow Moulding Process Step By Step - PVC Roofing Extrusion Line – JWELL , The product will supply to all over the world, such as: Mozambique, Bangladesh, Barbados, The products has a good reputation with competitive price, unique creation, leading the industry trends. The company insists on the principle of win-win idea, has establishedglobal sales network and after-sales service network.

Managers are visionary, they have the idea of mutual benefits, continuous improvement and innovation, we have a pleasant conversation and Cooperation.

Write your message here and send it to us