Best-Selling Polypropylene Extruder Machine - PP Honeycomb Board Extrusion Line – JWELL

Best-Selling Polypropylene Extruder Machine - PP Honeycomb Board Extrusion Line – JWELL Detail:

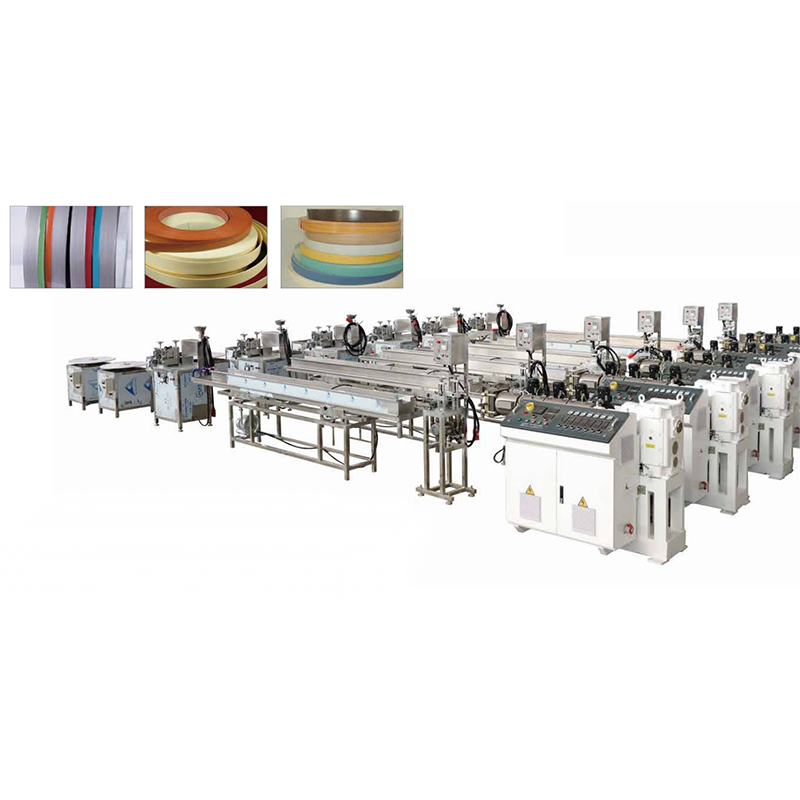

Product Presentation

PP honeycomb board through extrusion method made three layers sandwich board of one time forming, two sides is thin surface, middle is honeycomb structure; According to honeycomb structure can divide into single layer, double layer board. PP honeycomb board also can one time forming, coat fabric at two sides, leather, with light weight and high strength, non-toxic, environment, shake absorption and cold-resistant, soundproof& heat preservation, moistureproof& heat insulation etc.

Main technical parameter

| Mode | Suitable material | Products width(mm) | Products thickness(mm) | Capacity(kg/h |

| JWS75/75/75 | PP | 1200-1600 | 2-12 | 350-450 |

| JWS100/100/100 | PP | 1200-2000 | 2-20 | 600-700 |

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of employees building, striving hard to boost the standard and liability consciousness of staff members. Our corporation successfully attained IS9001 Certification and European CE Certification of Best-Selling Polypropylene Extruder Machine - PP Honeycomb Board Extrusion Line – JWELL , The product will supply to all over the world, such as: Uruguay, Albania, Karachi, Our tenet is integrity first, quality best. Now we have confidence in providing you with excellent service and ideal merchandise. We sincerely hope we can establish win-win business cooperation with you in the future!

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.

Write your message here and send it to us