factory customized Pvc Pipe Extrusion Process - Small Sized HDPE/PPR/PE-RT/PA Pipe Extrusion Line – JWELL

factory customized Pvc Pipe Extrusion Process - Small Sized HDPE/PPR/PE-RT/PA Pipe Extrusion Line – JWELL Detail:

Main Technical Parameter

Performance & Advantages

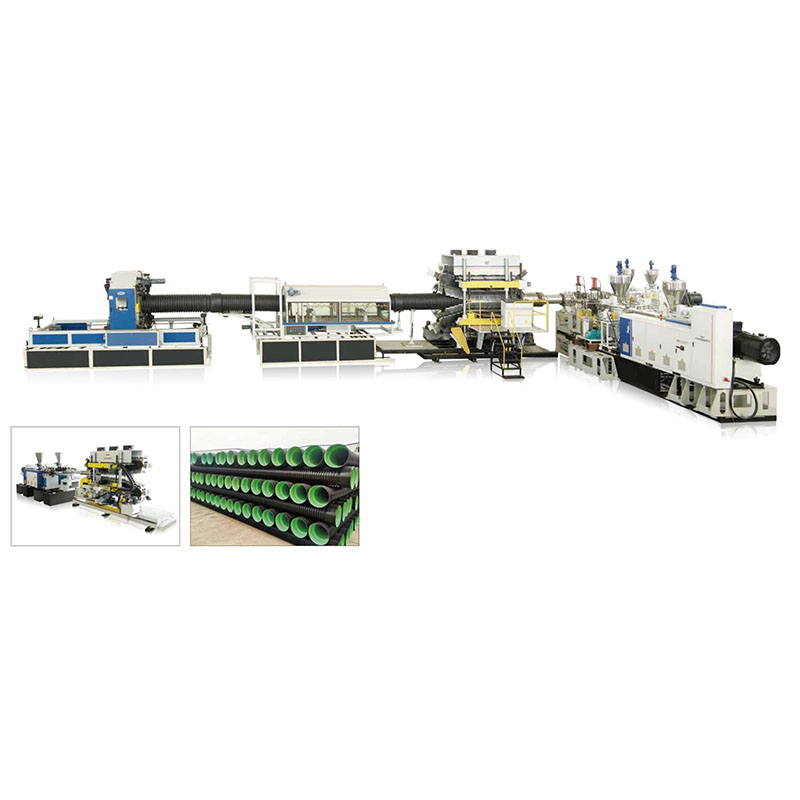

Servo-controlled high-speed double-belt haul off unit, supporting high-speed chipless cutter and winder, adapt to high-speed production operation.

Dual pipe extrusion line can double the output and occupy less factory space.

HDPE pipe is a flexible plastic pipe made of thermoplastic high-density polyethylene widely used for low-temperature fluid and gas transfer. In recent times, HDPE pipes got their extensive uses for carrying potable water, hazardous wastes, various gases, slurry, firewater, stormwater, etc. The strong molecular bond of HDPE pipe materials helps it to use for high-pressure pipelines. Polyethylene pipes have a long and distinguished service history for gas, oil, mining, water, and other industries. Due to its low weight and high corrosion resistance, the HDPE pipe industry is growing tremendously. In the year 1953, Karl Ziegler and Erhard Holzkamp discovered high-density polyethene (HDPE). HDPE pipes can work satisfactorily in a wide temperature range of -2200 F to +1800 F. However, the use of HDPE Pipes is not suggested when the fluid temperature exceeds 1220 F (500 C).

HDPE pipes are made by the polymerization of ethylene, a by-product of oil. Various additives (stabilizers, fillers, plasticizers, softeners, lubricants, colorants, flame retardants, blowing agents, crosslinking agents, ultraviolet degradable additives, etc.) are added to produce the final HDPE pipe and components. HDPE pipe lengths are made by heating the HDPE resin. It is then extruded through a die, which determines the diameter of the pipeline. The Pipe wall thickness is determined by a combination of the die size, speed of the screw, and the speed of the haul-off tractor. Usually, 3-5% carbon black is added to HDPE to make it UV resistant, which turns HDPE pipes into black in color. Other color variants are available but usually not used frequently. Coloured or striped HDPE pipe is usually 90-95% black material, where a colored stripe is provided on 5% of the outside surface.

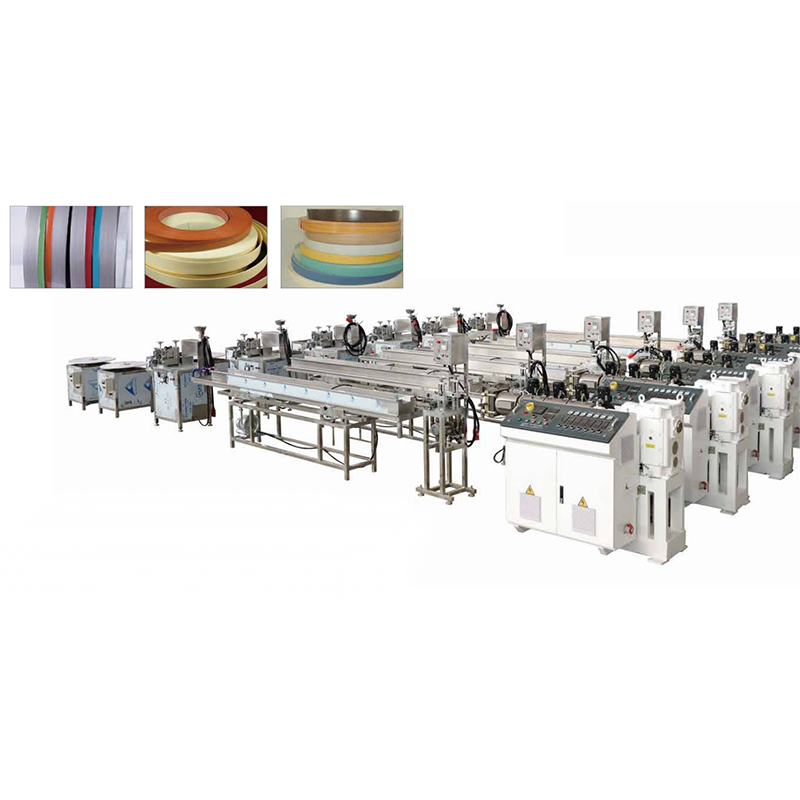

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for factory customized Pvc Pipe Extrusion Process - Small Sized HDPE/PPR/PE-RT/PA Pipe Extrusion Line – JWELL , The product will supply to all over the world, such as: Sao Paulo, Congo, Iraq, Our next goal is to exceed the expectations of every client by offering outstanding customer service, increased flexibility and greater value. All in all, without our customers we do not exist; without happy and fully satisfied customers, we fail. We are looking for the wholesale, Drop ship. Please contact us if you are interesting our products. Hope to do business with you all. High quality and fast shipment!

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!