Factory Free sample Plastic Extrusion Process Steps - PE Breathable Film Extrusion Line – JWELL

Factory Free sample Plastic Extrusion Process Steps - PE Breathable Film Extrusion Line – JWELL Detail:

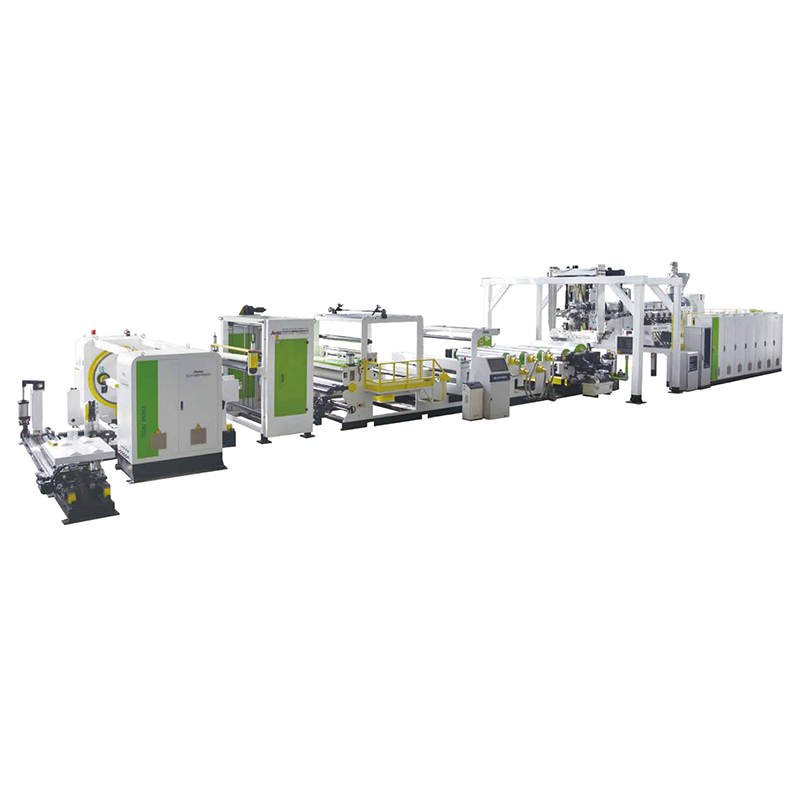

Product Presentation

The production line use PE air-permeable plastic granuels as raw material, and uses extrusion casting method to melt-extrude the PE-modified air-permeable plastic granuels containing inorganic filler through a flat die and the roller is stretched at a high rate to produce a sub-nanometer micro Porous membrane.

Main technical parameter

| Mode

JW130 |

Screw Diameter

130mm |

Materia

PE |

Products width

1600mm |

Capacity(Max.) 450-600kg/h | Main motor power

160KW |

| JW160 | 130mm | PE | 2200mm | 450-600kg/h | 200KW |

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of regard the market, regard the custom, regard the science as well as the theory of quality the basic, have confidence in the very first and management the advanced for Factory Free sample Plastic Extrusion Process Steps - PE Breathable Film Extrusion Line – JWELL , The product will supply to all over the world, such as: Portugal, Sydney, Malta, Good quality and reasonable price are our business principles. If you are interested in our products or have any questions, make sure you feel free to contact us. We hope to establish cooperative relationships with you in the near future.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly

Write your message here and send it to us