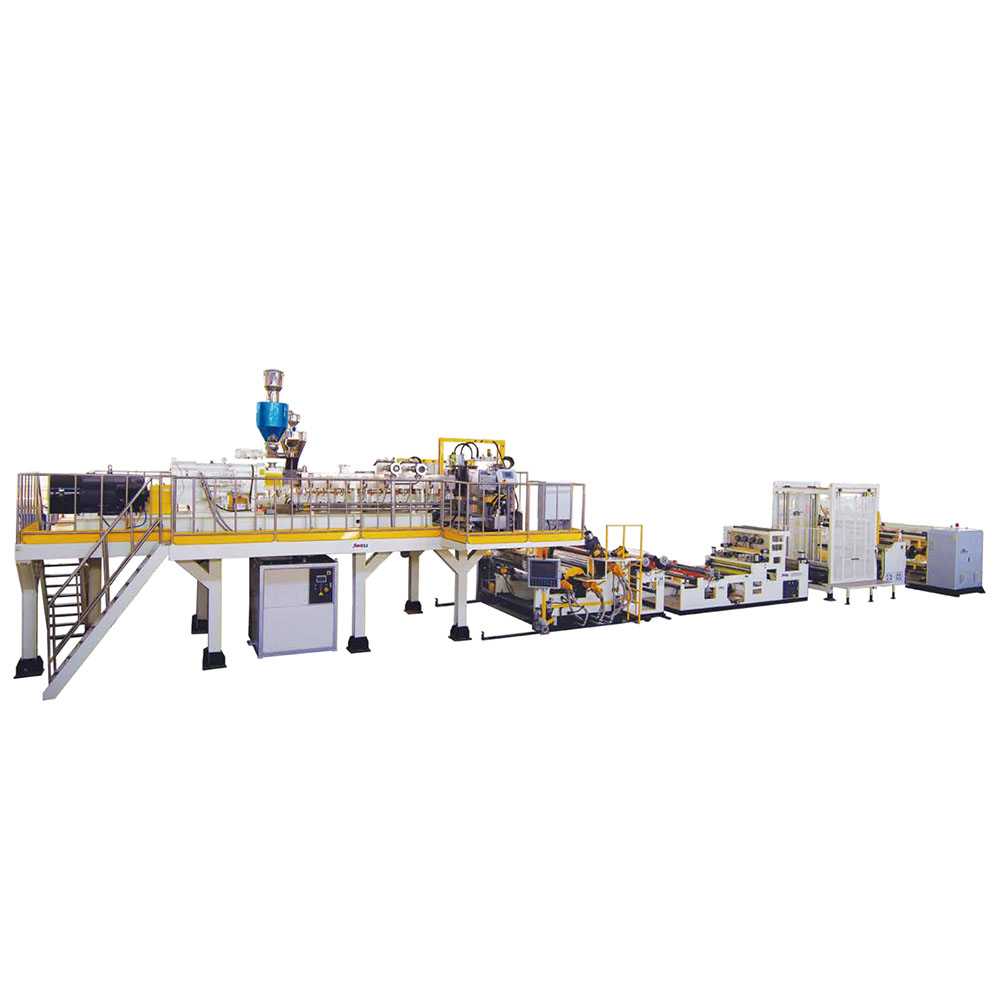

Factory Free sample Plastic Extrusion Process Steps - TPU Casting Composite Film Extrusion Line – JWELL

Factory Free sample Plastic Extrusion Process Steps - TPU Casting Composite Film Extrusion Line – JWELL Detail:

Product Presentation

TPU multi-group casting composite material is a kind of material which can realize 3-5 layers of different materials by multi-step casting and online combination. It has beautiful surface and can make different patterns. It has superior strength, wear resistance, safety and environmental protection performance. It is used in inflatable life jacket, diving BC jacket, life raft, hovercraft, inflatable tent, inflatable water bag, military inflatable self expansion mattress, massage air bag, medical protection, industrial conveyor belt and professional waterproof backpack.

This production line adopts multiple extruders and multiple sets of unwinding devices, step by step flow casting forming, and realizes one-step composite forming, which can be equipped with on-line multi-group thickness measurement control. The production line designs various composite methods and one production line can realize various production processes of product forms.For some special fabrics, it can be connected with the fabric pretreatment and gluing production line synchronously to meet the production needs of customers for different products.

Main technical specification

| Model | Products width(mm) | Products thickness(mm) | Capaditylko/h) |

| JWS120/JWS120 | 100o-3000 | 0.02-2.0 | 400-600 |

| Jws9o/Jws9oJws9o Jws9ows120/Jws9o |

1000-3000 | 0.02-2.0 | 250-350 |

| 100o-3000 | 0.02-2.0 | 350-450 |

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for Factory Free sample Plastic Extrusion Process Steps - TPU Casting Composite Film Extrusion Line – JWELL , The product will supply to all over the world, such as: Ethiopia, Turin, Barcelona, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

With a positive attitude of regard the market, regard the custom, regard the science, the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.