Factory made hot-sale Flat Film Extrusion Process - PET/PLA Sheet Extrusion Line – JWELL

Factory made hot-sale Flat Film Extrusion Process - PET/PLA Sheet Extrusion Line – JWELL Detail:

Main Technical Parameter

| Model | Extruder model | Products thickness(mm) | Main motor power(kw) | Max extrusion Capacity(kg/h) |

| Multi layer | JWE75/40+JWE52/40-1000 | 0.15-1.5 | 132/15 | 500-600 |

| Single layer | JWE75/40-1000 | 0.15-1.5 | 160 | 450-550 |

| Highly-efficient | JWE95/44+JWE65/44-1500 | 0.15-1.5 | 250/75 | 1000-1200 |

| Highly-efficient | JWE110+JWE65-1500 | 0.15-1.5 | 355/75 | 1000-1500 |

Note: The specifications are subject to change without prior notice.

Main Technical Parameter

| Model | Multi layer | Single layer | Highly-efficient |

| Extruder specification | JW120/65-1000 | JW120-1000 | JW150-1500 |

| Thickness of the product | 0.20-1.5mm | 0.2-1.5mm | 0.2-1.5mm |

| Main motor power | 132kw/45kw | 132kw | 200kw |

| Max extrusion capacity | 600-700kg/h | 550-650kg/h | 800-1000kg/h |

Note: The specifications are subject to change without prior notice.

PLA sheet

PLA is a kind of line shape Aliphatic Polyesters. PLA can be used in rigid package of fruits, vegetables, eggs, cooked food and roast food, also can be usedfor packaging of sandwich, biscuit and some other packages like fresh flower.

Product Description

Polylactic acid (PLA) can be completely decomposed into carbon dioxide and water under natural conditions after being discarded. It has good water resistance, mechanical properties, biocompatibility, can be absorbed by organisms, and has no pollution to the environment. At the same time, PLA also has good mechanical properties. It has high impact strength, good flexibility and thermal stability, plasticity, processability, no discoloration, good permeability to oxygen and water vapor, and good transparency, anti-mildew, antibacterial , the service life is 2~3 years.

The most important performance index of packaging materials is air permeability, and the application field of this material in packaging can be determined according to the different air permeability of materials. Some packaging materials require oxygen permeability to supply enough oxygen to the product; some packaging materials require a barrier to oxygen in terms of materials, such as beverage packaging, which requires materials that can prevent oxygen from entering the package to inhibit mold. effect of growth. PLA has gas barrier, water barrier, transparency and good printability.

PLA has good transparency and gloss, and its excellent performance is comparable to cellophane and PET, which is not available in other degradable plastics. The transparency and gloss of PLA are 2~3 times that of ordinary PP film and 10 times that of LDPE. Its high transparency makes the appearance of using PLA as a packaging material beautiful. For example, it is used for candy packaging. At present, many candy packagings on the market use PLA packaging films.

The appearance and performance of this packaging film are similar to traditional candy packaging films, with high transparency, excellent kink retention, printability and strength, as well as excellent barrier properties, which can better retain the flavor of candy . A Japanese company uses the “racea” brand PLA of the American Cakir Dow Polymer Company as the packaging material for new products, and the packaging is very transparent in appearance. Toray Industries has developed PLA functional films and slices using its proprietary nano-alloy technology. This film has the same heat and impact resistance as petroleum-based films, but also has excellent elasticity and transparency.

PLA can be made into film products with high transparency, good barrier properties, excellent processability and mechanical properties, and can be used for flexible packaging of fruits and vegetables. It can create a suitable storage environment for fruits and vegetables, maintain the life activities of fruits and vegetables, delay aging, and maintain the color, aroma, taste and appearance of fruits and vegetables. However, when applied to actual food packaging materials, some modifications are required to adapt to the characteristics of the food itself, so as to achieve a better packaging effect.

PLA can form a weakly acidic environment on the surface of the product, which has the basis of antibacterial and antifungal. If other antibacterial agents are used in addition, the antibacterial rate of more than 90% can be achieved, which can be used for antibacterial packaging of products.

Compared with LDPE film, PLA film and PLA/REO/TiO2 film, the water permeability of PLA/REO/Ag composite film is significantly higher than that of other films. It is concluded from this that it can effectively prevent the formation of condensed water and achieve the effect of inhibiting the growth of microorganisms; at the same time, it also has an excellent bacteriostatic effect.

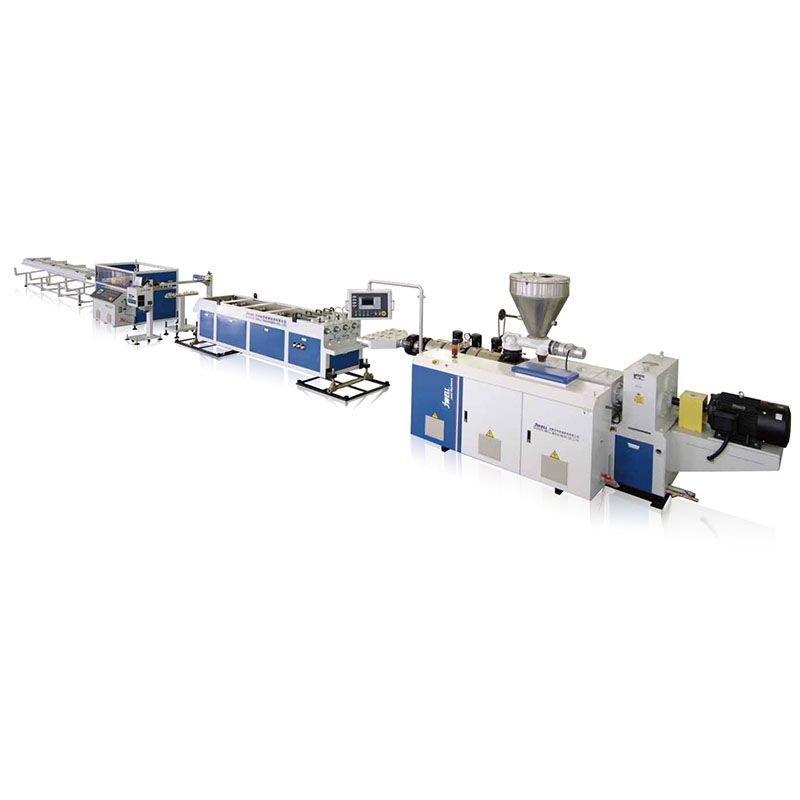

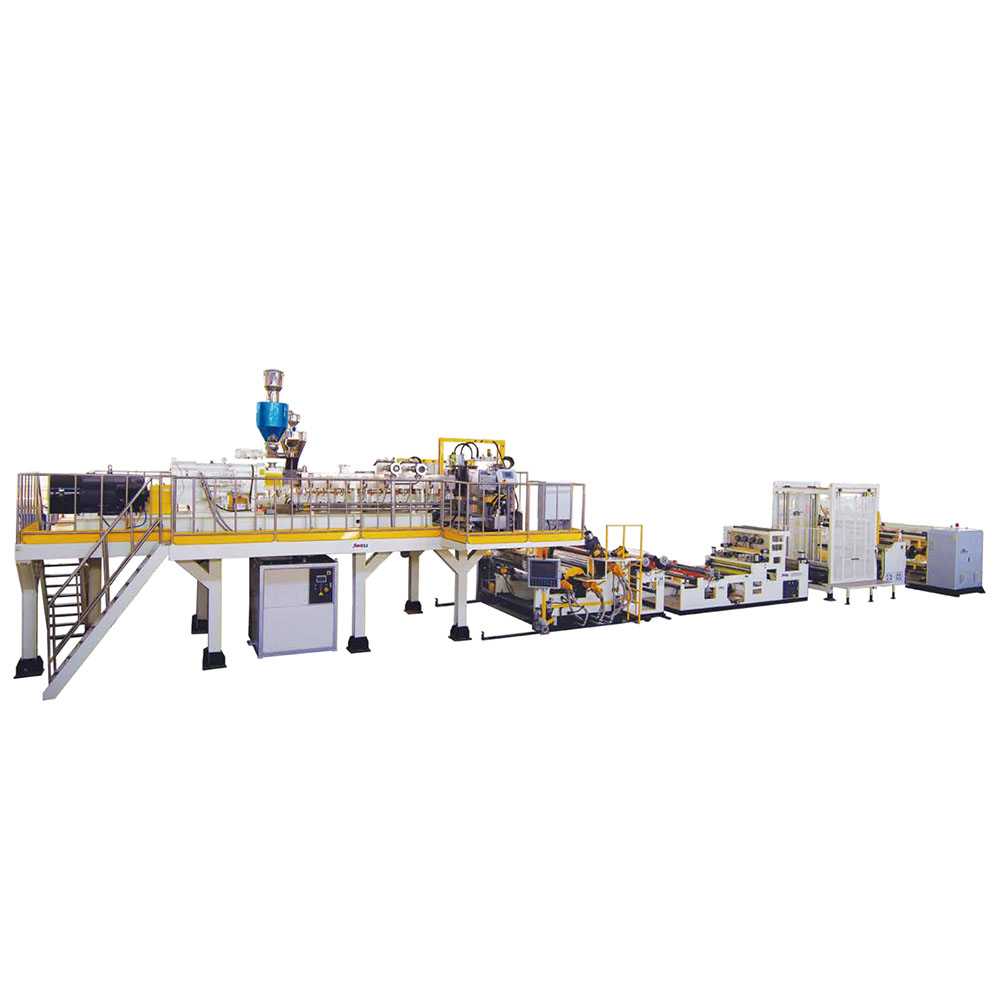

PET/PLA environmental sheet extrusion line: JWELL develops the parallel twin screw extrusion line for PET/PLA sheet, this line equipped with degassing system, and no need drying and crystallizing unit. The extrusion line has the properties of low energy comsuption, simple production process and easy maintenance. The segmented screw structure can reduce the viscosity loss of PET/PLA resin, the symmetrical and thin-wall calender roller highten the cooling effect and improve the capactity and sheet quality. Multi components dosing feeder can control the percentage of virgin material, recycling material and master batch precisely, the sheet is widely used for thermoforming packaging industry.

Product detail pictures:

Related Product Guide:

With our leading technology as well as our spirit of innovation,mutual cooperation, benefits and development, we will build a prosperous future together with your esteemed company for Factory made hot-sale Flat Film Extrusion Process - PET/PLA Sheet Extrusion Line – JWELL , The product will supply to all over the world, such as: Costa Rica, Victoria, Marseille, Our staffs are adhering to the Integrity-based and Interactive Development spirit, and the tenet of First-class Quality with Excellent Service. According to the needs of every customer, we give customized & personalised services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

Hope that the company could stick to the enterprise spirit of Quality, Efficiency, Innovation and Integrity, it will be better and better in the future.