Featured

-

Excellent quality Extruded Pe - PVC Foaming Board Extrusion Line – JWELL

Product Presentation PVC foam board also named Snow board and Andy board, the chemical component is polyvinyl chloride, also can be named foam polyvinyl chloride board. PVC Semi-Skinning foam manufacturing technique is combine free foam technique and semi-skinning foam to develop new technology, this equipment have advanced structure,simple formulation,easy operation etc. The feature of PVC Semi-Skinning foam board 1.Waterproof,anti-flame,anti-acid& akali,anti-moth,light weig... -

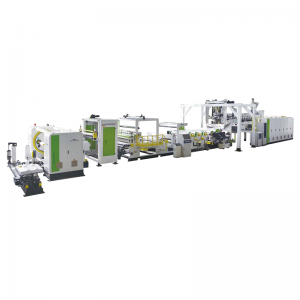

Europe style for Plastic Recycling Machine Cost - PVC Flooring Rolls Extrusion Line – JWELL

Application and Feature It is made of different colors of PVC crushed material, adopting even proportion and thermo-pressing. Because of its environmental protection,ornamental value as well as each maintenance, it is widely used for housing, hospital, school, factory, hotel, and restaurant decoration. This line features of easy operation and high technical, which is for producing different colors pattern . Product thickness is 2-3mm; width is 2000mm. -

Quality Inspection for Extrusion Process In Plastic - PP/PE Solar Photovoltaic Cell Backsheet Extrusion Line – JWELL

Solar cell backsheet It is an important part of the solar photovoltaic cell structure and plays an insulating and protective role on the solar photovoltaic cell. There are many types of solar cell backsheets on the market, the design life is generally 25 years, and the design life of the transparent backsheet is 30 years This production line is used to produce high-performance, innovative fluorine-free solar photovoltaic backsheets that conform to the trend of green manufacturing; the pr... -

Discount wholesale Plastic Recycling Conference - Stretch Film Extrusion Line – JWELL

Product Presentation Stretch film production line is mainly used for PE lithium electric film; PP,PE breathable film; PP, PE, PET, PS thermo-shrinkage packing industrial. The equipment is composed by extruder, die head, sheet cast, lognitudinal stretch, transverse stretching, automatic winder and controlling system. Relying on our advanced designing and processing ability, our equipment’s features are: ● Special designed lognitudinal strech roller ● Driving and controlling system are f... -

Factory Free sample Extruder Machine Working - HDPE/PP T-Grip Sheet Extrusion Line – JWELL

Product Presentation T-grip sheet is mainly used in basis construction concrete casting of the construction joints and deformation constitute the basis of engineering for the integration and joints of concrete, such as tunnel, culvert, aqueduct, dam, reservoir structures, underground facilities; Main technical parameter Model JWS120-1 JWS150- | Width of sheet 1000-1500mm 2000-3000mm Maxim extrusion output 350kg/h 500kg/h -

Good User Reputation for Polyethylene Film Extrusion - HDPE/PP T-Grip Sheet Extrusion Line – JWELL

Product Presentation T-grip sheet is mainly used in basis construction concrete casting of the construction joints and deformation constitute the basis of engineering for the integration and joints of concrete, such as tunnel, culvert, aqueduct, dam, reservoir structures, underground facilities; Main technical parameter Model JWS120-1 JWS150- | Width of sheet 1000-1500mm 2000-3000mm Maxim extrusion output 350kg/h 500kg/h -

New Fashion Design for Plastic Maker Machine - EVA/POE Solar Film Extrusion Line – JWELL

Main Technical Parameter Model Extruder type Products thickness(mm) Max. output Single extrusion JWS200 0.2-1.0 500-600 Co-extrusion JWS160+JWS180 0.2-1.0 750-850 Co-extrusion JWS180+JWS180 0.2-1.0 800-1000 Co-extrusion JWS180+JWS200 0.2-1.0 900-1100 Note: The specifications are subject to change without prior notice. Product Description The advantages of solar cell encapsulation film (EVA) are summarized as follows: 1. High transparency and high adhesion can be applied ... -

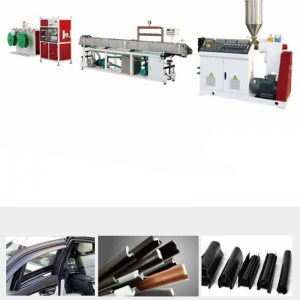

Factory best selling Hdpe Profile Extrusion - PVC/TPE/TPE Sealing Extrusion Line – JWELL

Product Presentation The machine is used for producing sealing strip of PVC, TPU, TPE etc material, features high output, steady extrusion, low power consuption. Adapting famous inverter, SIEMENS PLC and screen, easy operation and maintenance. Technical parameter Extruder model JWS45/25 JWS65/25 Motor power(kw) 7.5 18.5 Output (kg/h) 15-25 40-60 Cooling water (m3/h) 3 4 -

Leading Manufacturer for Extrusion Profile - PS Foaming Frame Extrusion Line – JWELL

Product Presentation YF Series PS Foam Profile Extrusion Line, consists of single screw extruder and the special co-extruder, with the cooling water tank, hot stamping machine system, haul-off unit, and stacker. This line with imported ABB AC inverter control, im- ported RKC temperature meter etc. and features of good plastification, high output capacity, and stable performance etc.The hot stamping machine system combined foreign technology, by the hot stamping embossing method, transfer... -

Factory Supply Thermoplastic Extruder - High Polymer Waterproof Rolls Extrusion Line – JWELL

PE waterproofing membrane performance and advantages 1. The construction is convenient, the construction period is short, no maintenance is required after forming, it is not affected by temperature, the environmental pollution is small, the layer thickness is easy to grasp according to the design requirements, the material calculation is accurate, the construction site management is convenient, the layer thickness is uniform, and can be effectively overcome when empty. Base stress (maint... -

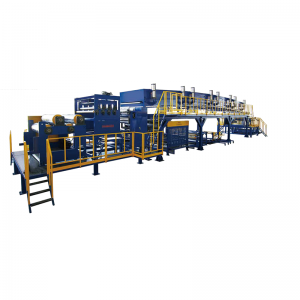

One of Hottest for Extruder Screw Barrel - LFT/CFP/FRP/CFRT Continuous Fiber Reinforced – JWELL

Composite Production Line Continuous fiber reinforced composite material is made of reinforced fiber material: glass fiber(GF), carbon fiber(CF), aramid fiber(AF), ultra high molecular polyethylene fiber(UHMW-PE), basalt fiber(BF) by using special process technology to makes high strength continuous fiber and thermal plastic&thermosetting resin soak with each other. Then extrusion and drawing process are used to form the high strength, high toughness and recyclable thermalplastic re... -

18 Years Factory Plastic Sheet Extrusion - Stretch Film Extrusion Line – JWELL

Product Presentation Stretch film production line is mainly used for PE lithium electric film; PP,PE breathable film; PP, PE, PET, PS thermo-shrinkage packing industrial. The equipment is composed by extruder, die head, sheet cast, lognitudinal stretch, transverse stretching, automatic winder and controlling system. Relying on our advanced designing and processing ability, our equipment’s features are: ● Special designed lognitudinal strech roller ● Driving and controlling system are f...