Featured

-

Factory making 3 Layer Extrusion Machine - PVC Foaming Board Extrusion Line – JWELL

Product Presentation PVC foam board also named Snow board and Andy board, the chemical component is polyvinyl chloride, also can be named foam polyvinyl chloride board. PVC Semi-Skinning foam manufacturing technique is combine free foam technique and semi-skinning foam to develop new technology, this equipment have advanced structure,simple formulation,easy operation etc. The feature of PVC Semi-Skinning foam board 1.Waterproof,anti-flame,anti-acid& akali,anti-moth,light weig... -

Chinese wholesale Co Extrusion Plastic - PP/PE Solar Photovoltaic Cell Backsheet Extrusion Line – JWELL

Solar cell backsheet It is an important part of the solar photovoltaic cell structure and plays an insulating and protective role on the solar photovoltaic cell. There are many types of solar cell backsheets on the market, the design life is generally 25 years, and the design life of the transparent backsheet is 30 years This production line is used to produce high-performance, innovative fluorine-free solar photovoltaic backsheets that conform to the trend of green manufacturing; the pr... -

OEM China Plastic Recycling Extruder Machine - TPU Glass Interlayer Film Extrusion Line – JWELL

Application Aerospace, high-speed trains, military and civilian helicopters, passenger aircraft, transport aircraft windshield, bullet-proof armor, bank explosion-proof, photovoltaic and other industries. Main technical specification Mode Products width(mm Products thickness(mm) Design max capacity(kg/h JWS130 1400-2000 0.3-1.8 200-300 JWS150 1600-2200 0.3-1.8 300-400 -

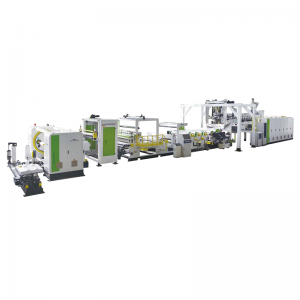

Professional China Pvc Sheet Machine - PVC High Speed Profile Extrusion Line – JWELL

Properties and advantages This line features stable plasticization, high output,low sheering force,long life service and other advantages. The production line consists of control system, conical twin screw extruder or parallel twin screw extruder,extrusion die, calibration unit,haul off unit, film covering machine and stacker. The extruder is equipped with AC variable frequency or DC speed drive, imported temperature controller. The calibration unit’s pump and haul off unit’s... -

Good User Reputation for Acrylic Sheet Extruder - PVC Foaming Board Extrusion Line – JWELL

Product Presentation PVC foam board also named Snow board and Andy board, the chemical component is polyvinyl chloride, also can be named foam polyvinyl chloride board. PVC Semi-Skinning foam manufacturing technique is combine free foam technique and semi-skinning foam to develop new technology, this equipment have advanced structure,simple formulation,easy operation etc. The feature of PVC Semi-Skinning foam board 1.Waterproof,anti-flame,anti-acid& akali,anti-moth,light weig... -

Cheap price Plastic Extruder Screw Design - EVA/POE Solar Film Extrusion Line – JWELL

Main Technical Parameter Model Extruder type Products thickness(mm) Max. output Single extrusion JWS200 0.2-1.0 500-600 Co-extrusion JWS160+JWS180 0.2-1.0 750-850 Co-extrusion JWS180+JWS180 0.2-1.0 800-1000 Co-extrusion JWS180+JWS200 0.2-1.0 900-1100 Note: The specifications are subject to change without prior notice. Product Description The advantages of solar cell encapsulation film (EVA) are summarized as follows: 1. High transparency and high adhesion can be applied ... -

Free sample for Extruder Machine Use - PVC Foaming Board Extrusion Line – JWELL

Product Presentation PVC foam board also named Snow board and Andy board, the chemical component is polyvinyl chloride, also can be named foam polyvinyl chloride board. PVC Semi-Skinning foam manufacturing technique is combine free foam technique and semi-skinning foam to develop new technology, this equipment have advanced structure,simple formulation,easy operation etc. The feature of PVC Semi-Skinning foam board 1.Waterproof,anti-flame,anti-acid& akali,anti-moth,light weig... -

Cheapest Factory Blow Molding Extrusion - PC Hollow Cross Section Sheet Extrusion Line – JWELL

PC hollow sheet, U-shaped/U locked sheet extrusion line ●Construction of sunroof in buildings ,halls, shopping center, stadium, public places of entertainment and public facility. ●Rain shield of bus stations ,garages, pergolas, corridors. ●Transparent shields for security forces in nursery schools airports, factories. Main technical parameter Model Products width(mm) Productsthickness(mm) Desigmed capacitykgh) WS100+JWS45 1220 4-40 350 JWS120+JWS45 210o 4-40 450 -

China Supplier Plastic Extrusion Machinery - TPU Glass Interlayer Film Extrusion Line – JWELL

Application Aerospace, high-speed trains, military and civilian helicopters, passenger aircraft, transport aircraft windshield, bullet-proof armor, bank explosion-proof, photovoltaic and other industries. Main technical specification Mode Products width(mm Products thickness(mm) Design max capacity(kg/h JWS130 1400-2000 0.3-1.8 200-300 JWS150 1600-2200 0.3-1.8 300-400 -

Fast delivery Hdpe Sheet Extruder - PP/PS Sheet Extrusion Line – JWELL

Product Presentation Developed by Jwell company, this line is for producing multi-layer environmental-friendly sheet, which is widely used for vacuum forming, green food container and package, different kinds of food packaging container, such as: salver,bowl, canteen, fruit dish, etc. Adopting maxim talc percentage in the sheet production, either customer will be able to reduce the cost of the sheet or increase the sheet degration character as well as gaining good physical properties an... -

OEM/ODM China Sheet Film Extrusion - PET/PLA Sheet Extrusion Line – JWELL

Main Technical Parameter Model Extruder model Products thickness(mm) Main motor power(kw) Max extrusion Capacity(kg/h) Multi layer JWE75/40+JWE52/40-1000 0.15-1.5 132/15 500-600 Single layer JWE75/40-1000 0.15-1.5 160 450-550 Highly-efficient JWE95/44+JWE65/44-1500 0.15-1.5 250/75 1000-1200 Highly-efficient JWE110+JWE65-1500 0.15-1.5 355/75 1000-1500 Note: The specifications are subject to change without prior notice. Main Technical Parameter Model Multi layer Sin... -

High Quality for Plastic Extrusion Cost - PP/PE/PA/PETG/EVOH Multilayer Barrier Sheet Co-extrusion Line – JWELL

Main Technical Parameter Line model Extruder model Products width Products thickness Design extrusion output 7 layers co-extrusion 120/75/50/60/75 800-1200mm 0.2-0.5mm 500-600kg/h 9 layers co-extrusion 75/100/60/65/50/75/75 800-1200mm 0.05-0.5mm 700-800kg/h Note: The specifications are subject to change without prior notice. Market status of EVOH packaging applications In the field of cold chain food packaging, people used metal or glass materials as food packaging to effective...