Featured

-

Best Price on Plastic Intrusion - EVA/POE Solar Film Extrusion Line – JWELL

Main Technical Parameter Model Extruder type Products thickness(mm) Max. output Single extrusion JWS200 0.2-1.0 500-600 Co-extrusion JWS160+JWS180 0.2-1.0 750-850 Co-extrusion JWS180+JWS180 0.2-1.0 800-1000 Co-extrusion JWS180+JWS200 0.2-1.0 900-1100 Note: The specifications are subject to change without prior notice. Product Description The advantages of solar cell encapsulation film (EVA) are summarized as follows: 1. High transparency and high adhesion can be applied ... -

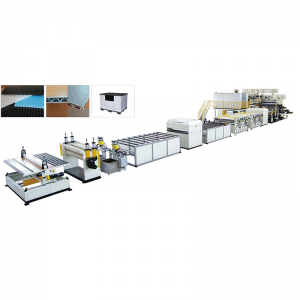

Free sample for Extruder Machine Use - PP Honeycomb Board Extrusion Line – JWELL

Product Presentation PP honeycomb board through extrusion method made three layers sandwich board of one time forming, two sides is thin surface, middle is honeycomb structure; According to honeycomb structure can divide into single layer, double layer board. PP honeycomb board also can one time forming, coat fabric at two sides, leather, with light weight and high strength, non-toxic, environment, shake absorption and cold-resistant, soundproof& heat preservation, moistureproof&... -

Fast delivery Plastic Extruder Parts - EVA/POE Solar Film Extrusion Line – JWELL

Main Technical Parameter Model Extruder type Products thickness(mm) Max. output Single extrusion JWS200 0.2-1.0 500-600 Co-extrusion JWS160+JWS180 0.2-1.0 750-850 Co-extrusion JWS180+JWS180 0.2-1.0 800-1000 Co-extrusion JWS180+JWS200 0.2-1.0 900-1100 Note: The specifications are subject to change without prior notice. Product Description The advantages of solar cell encapsulation film (EVA) are summarized as follows: 1. High transparency and high adhesion can be applied ... -

Manufacturing Companies for Plastic Film Extrusion Equipment - PE Breathable Film Extrusion Line – JWELL

Product Presentation The production line use PE air-permeable plastic granuels as raw material, and uses extrusion casting method to melt-extrude the PE-modified air-permeable plastic granuels containing inorganic filler through a flat die and the roller is stretched at a high rate to produce a sub-nanometer micro Porous membrane. Main technical parameter Mode JW130 Screw Diameter 130mm Materia PE Products width 1600mm Capacity(Max.) 450-600kg/h Main motor power 160KW JW160 130... -

OEM Factory for Plastic Extruders - TPU Casting Composite Film Extrusion Line – JWELL

Product Presentation TPU multi-group casting composite material is a kind of material which can realize 3-5 layers of different materials by multi-step casting and online combination. It has beautiful surface and can make different patterns. It has superior strength, wear resistance, safety and environmental protection performance. It is used in inflatable life jacket, diving BC jacket, life raft, hovercraft, inflatable tent, inflatable water bag, military inflatable self expansion mattr... -

100% Original Plastic Compounding Equipment - EVA/POE Solar Film Extrusion Line – JWELL

Main Technical Parameter Model Extruder type Products thickness(mm) Max. output Single extrusion JWS200 0.2-1.0 500-600 Co-extrusion JWS160+JWS180 0.2-1.0 750-850 Co-extrusion JWS180+JWS180 0.2-1.0 800-1000 Co-extrusion JWS180+JWS200 0.2-1.0 900-1100 Note: The specifications are subject to change without prior notice. Product Description The advantages of solar cell encapsulation film (EVA) are summarized as follows: 1. High transparency and high adhesion can be applied ... -

100% Original Factory Pelletizing Machine - PVC Foaming Board Extrusion Line – JWELL

Product Presentation PVC foam board also named Snow board and Andy board, the chemical component is polyvinyl chloride, also can be named foam polyvinyl chloride board. PVC Semi-Skinning foam manufacturing technique is combine free foam technique and semi-skinning foam to develop new technology, this equipment have advanced structure,simple formulation,easy operation etc. The feature of PVC Semi-Skinning foam board 1.Waterproof,anti-flame,anti-acid& akali,anti-moth,light weig... -

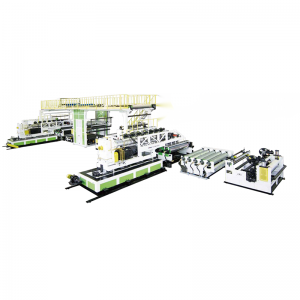

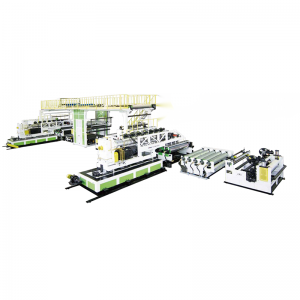

Wholesale Difference Between Extrusion And Injection Molding - PP/PE Hollow Cross Section Sheet Extrusion Line – JWELL

Application ●The pp hollow cross section plate is light and high strength, moistureproof good environmental protection and re-fabrication performance. ●Can be processed into the reusable container, packing case, clapboard, backing plate and culet. Main technical parameter Model Products width(mm) Products thickness(mm) Designed capacity(kg/h) JWS120 1200-2100 2-8 350 JWS150 1200-2600 2-8 500 WS100+JWS65 915 12-16 400 WS150+JWS90 2000 12-16 600 -

Manufacturer of Pvc Extrusion Line - WPC Decking Extrusion Line – JWELL

Product Presentation WPC (PE&PP)Wood-Plastic Floor is that the wood-plastic composite materials complete in different equipment of mixing, from play, extruding products, mixing the raw material in a certain formula, forming wood-plastic particles in the middle, and then squeezing out products. And nowadays, the two-step way is used currently, application of a wider general use dual-cone-or two-extruder extruder granulation, and then double-cone or single screw extruder extrusion prod... -

Best quality Die Head Extruder - Alumium Plastic Composite Panel Extrusion Line – JWELL

Main Technical Parameter Model Products width(mm) Products thickness(mm) Design max capacity(kg/h) JWS170/35 900-1220 1-6 500-600 JWS180/35 900-1560 1-6 700-800 SJZ85/170 900-2000 1-6 1000-1200 SJZ95/203 900-2000 1-6 1200-1600 JWP135/48 900-2000 2-6 1600-2500 Note: The specifications are subject to change without prior notice. Product Description [Aluminum-plastic panel] is composed of two materials (metal and non-metal) with completely different properties. It not only ... -

OEM manufacturer Plastic Extrusion Materials - TPU Casting Composite Film Extrusion Line – JWELL

Product Presentation TPU multi-group casting composite material is a kind of material which can realize 3-5 layers of different materials by multi-step casting and online combination. It has beautiful surface and can make different patterns. It has superior strength, wear resistance, safety and environmental protection performance. It is used in inflatable life jacket, diving BC jacket, life raft, hovercraft, inflatable tent, inflatable water bag, military inflatable self expansion mattr... -

Factory Outlets Plastic Profile Extruders - High Polymer Waterproof Rolls Extrusion Line – JWELL

PE waterproofing membrane performance and advantages 1. The construction is convenient, the construction period is short, no maintenance is required after forming, it is not affected by temperature, the environmental pollution is small, the layer thickness is easy to grasp according to the design requirements, the material calculation is accurate, the construction site management is convenient, the layer thickness is uniform, and can be effectively overcome when empty. Base stress (maint...