Featured

-

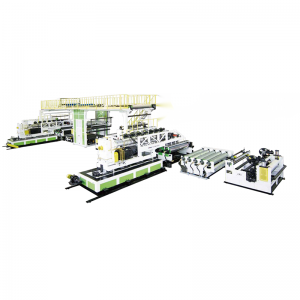

Best quality Die Head Extruder - HDPE Waterdrainage Sheet Extrusion Line – JWELL

Product Presentation Water Drainage Sheet: It is made of HDPE material, outer figure is of cone salient, functions of draining water and storing water, features of high stiffness and pressure resistance. Advantages: Traditional drainage water prefers brick tile and cobblestone for draining water. Water drainage sheet is used for replacing the traditional method to save time, energy, investment and reduce load of building. Application: Used for underground construction or roofing green. ... -

Popular Design for Extrusion Polystyrene - PVC Sheet Extrusion Line – JWELL

Product Presentation PVC transparent sheet have many advantages of fire-resistance, high quality, low cost, high transparent, good surface, no spot,less water wave, high strike resistance, easy to mould and etc. It is applied to different kinds of packing ,vacuuming and case, such as tools, toys, electronic, food, medicine and clothes. Product application: For decoration in hotel,restaurant,office, inner wall of villa,kitchen,toilet and it can be used or outside wall decoration,celling,... -

100% Original Factory Foam Sheet Extrusion Line - PET/PLA Sheet Extrusion Line – JWELL

Main Technical Parameter Model Extruder model Products thickness(mm) Main motor power(kw) Max extrusion Capacity(kg/h) Multi layer JWE75/40+JWE52/40-1000 0.15-1.5 132/15 500-600 Single layer JWE75/40-1000 0.15-1.5 160 450-550 Highly-efficient JWE95/44+JWE65/44-1500 0.15-1.5 250/75 1000-1200 Highly-efficient JWE110+JWE65-1500 0.15-1.5 355/75 1000-1500 Note: The specifications are subject to change without prior notice. Main Technical Parameter Model Multi layer Sin... -

Wholesale Difference Between Extrusion And Injection Molding - PP/PE Hollow Cross Section Sheet Extrusion Line – JWELL

Application ●The pp hollow cross section plate is light and high strength, moistureproof good environmental protection and re-fabrication performance. ●Can be processed into the reusable container, packing case, clapboard, backing plate and culet. Main technical parameter Model Products width(mm) Products thickness(mm) Designed capacity(kg/h) JWS120 1200-2100 2-8 350 JWS150 1200-2600 2-8 500 WS100+JWS65 915 12-16 400 WS150+JWS90 2000 12-16 600 -

Best-Selling Polypropylene Extruder Machine - PP/PE Hollow Cross Section Sheet Extrusion Line – JWELL

Application ●The pp hollow cross section plate is light and high strength, moistureproof good environmental protection and re-fabrication performance. ●Can be processed into the reusable container, packing case, clapboard, backing plate and culet. Main technical parameter Model Products width(mm) Products thickness(mm) Designed capacity(kg/h) JWS120 1200-2100 2-8 350 JWS150 1200-2600 2-8 500 WS100+JWS65 915 12-16 400 WS150+JWS90 2000 12-16 600 -

Renewable Design for Plastic Sheet Extrusion Process - PET Decorative Film Extrusion Line – JWELL

Product Presentation PET decorative film is a kind of film processed with a unique formula. With high-end printing technology and embossing technology, it shows various forms of color patterns and high-grade textures. The product has natural wood texture, high-grade metal texture, elegant skin texture, high-gloss surface texture and other forms of expression. At the same time, it provides a variety of choices according to consumer needs. Because of its unique construction and paste treat... -

Renewable Design for Plastic Sheet Extrusion Process - Stretch Film Extrusion Line – JWELL

Product Presentation Stretch film production line is mainly used for PE lithium electric film; PP,PE breathable film; PP, PE, PET, PS thermo-shrinkage packing industrial. The equipment is composed by extruder, die head, sheet cast, lognitudinal stretch, transverse stretching, automatic winder and controlling system. Relying on our advanced designing and processing ability, our equipment’s features are: ● Special designed lognitudinal strech roller ● Driving and controlling system are f... -

Chinese Professional Co Extrusion Process - Alumium Plastic Composite Panel Extrusion Line – JWELL

Main Technical Parameter Model Products width(mm) Products thickness(mm) Design max capacity(kg/h) JWS170/35 900-1220 1-6 500-600 JWS180/35 900-1560 1-6 700-800 SJZ85/170 900-2000 1-6 1000-1200 SJZ95/203 900-2000 1-6 1200-1600 JWP135/48 900-2000 2-6 1600-2500 Note: The specifications are subject to change without prior notice. Product Description [Aluminum-plastic panel] is composed of two materials (metal and non-metal) with completely different properties. It not only ... -

Factory Price For Plastic Processing Machine - PVC Flooring Rolls Extrusion Line – JWELL

Application and Feature It is made of different colors of PVC crushed material, adopting even proportion and thermo-pressing. Because of its environmental protection,ornamental value as well as each maintenance, it is widely used for housing, hospital, school, factory, hotel, and restaurant decoration. This line features of easy operation and high technical, which is for producing different colors pattern . Product thickness is 2-3mm; width is 2000mm. -

2022 High quality Pet Extruder Machine - PP/PE Hollow Cross Section Sheet Extrusion Line – JWELL

Application ●The pp hollow cross section plate is light and high strength, moistureproof good environmental protection and re-fabrication performance. ●Can be processed into the reusable container, packing case, clapboard, backing plate and culet. Main technical parameter Model Products width(mm) Products thickness(mm) Designed capacity(kg/h) JWS120 1200-2100 2-8 350 JWS150 1200-2600 2-8 500 WS100+JWS65 915 12-16 400 WS150+JWS90 2000 12-16 600 -

Hot Selling for Plastic Profile Extrusion Process - TPU Casting Composite Film Extrusion Line – JWELL

Product Presentation TPU multi-group casting composite material is a kind of material which can realize 3-5 layers of different materials by multi-step casting and online combination. It has beautiful surface and can make different patterns. It has superior strength, wear resistance, safety and environmental protection performance. It is used in inflatable life jacket, diving BC jacket, life raft, hovercraft, inflatable tent, inflatable water bag, military inflatable self expansion mattr... -

Manufactur standard Plastik Di - PP/PE/ABS/PVC Thick Board Extrusion Line – JWELL

Product Presentation PP thick plate, is an environmentally-friendly product and is widely applied in chemistry industry, food industry, anti-erosion industry, environmentally-friendly equipments industry, etc. PP thick plate extrusion line of 2000mm width is a newly developed line which is the most advanced and stable line compared with other competitors. PE thick plate extrusion line PE plate is widely applied in chemical and electric power industries. HDPE plate, known as engineerin...