Good User Reputation for Polyethylene Film Extrusion - PP Honeycomb Board Extrusion Line – JWELL

Good User Reputation for Polyethylene Film Extrusion - PP Honeycomb Board Extrusion Line – JWELL Detail:

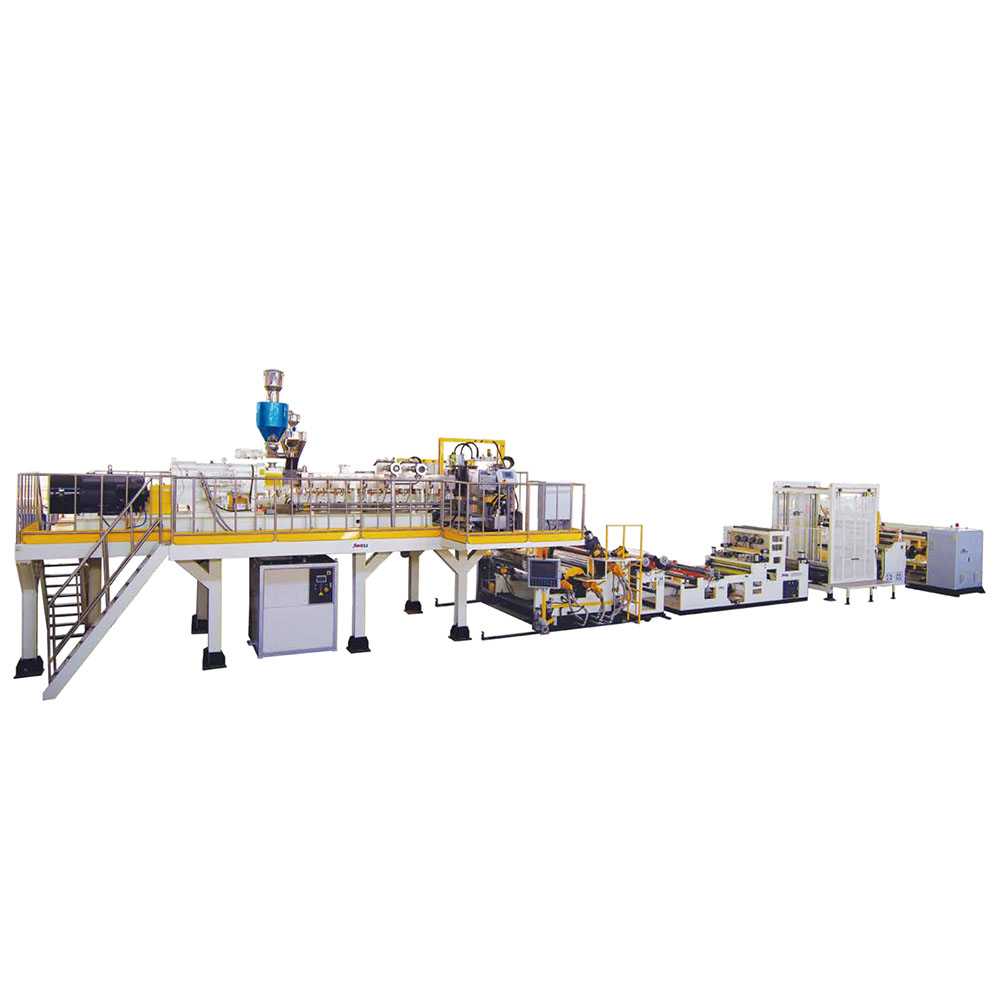

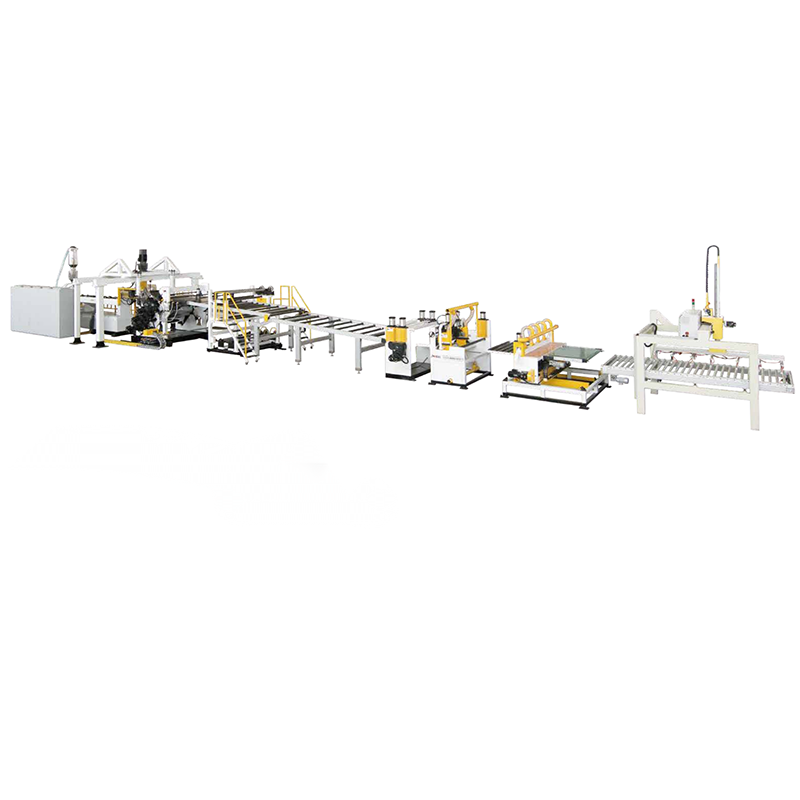

Product Presentation

PP honeycomb board through extrusion method made three layers sandwich board of one time forming, two sides is thin surface, middle is honeycomb structure; According to honeycomb structure can divide into single layer, double layer board. PP honeycomb board also can one time forming, coat fabric at two sides, leather, with light weight and high strength, non-toxic, environment, shake absorption and cold-resistant, soundproof& heat preservation, moistureproof& heat insulation etc.

Main technical parameter

| Mode | Suitable material | Products width(mm) | Products thickness(mm) | Capacity(kg/h |

| JWS75/75/75 | PP | 1200-1600 | 2-12 | 350-450 |

| JWS100/100/100 | PP | 1200-2000 | 2-20 | 600-700 |

Product detail pictures:

Related Product Guide:

In order to best meet client's needs, all of our operations are strictly performed in line with our motto High Quality, Competitive Price, Fast Service for Good User Reputation for Polyethylene Film Extrusion - PP Honeycomb Board Extrusion Line – JWELL , The product will supply to all over the world, such as: Plymouth, Oman, Qatar, Over the years, with high-quality solutions, first- class service, ultra-low prices we win thee trust and favor of customers. Nowadays our products sell all over the domestic and abroad. Thanks for the regular and new customers support. We offer high quality product and competitive price, welcome the regular and new customers cooperate with us!

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.

Write your message here and send it to us