High definition Pipe Extrusion Process - Parallel/Conical Twin Screw HDPE/PP/PVC DWC Pipe Extrusion Line – JWELL

High definition Pipe Extrusion Process - Parallel/Conical Twin Screw HDPE/PP/PVC DWC Pipe Extrusion Line – JWELL Detail:

Main Technical Parameter

| Type | Pipe diameter | HDPE output | Max speed(m/min) | Total power |

| JWSBL-600 | 200-600 | 800 | 5.0 | 500 |

| JWSBL-1000 | 200-1000 | 1200 | 2.5 | 710 |

| JWSBL-1200 | 800-1200 | 1400 | 1.5 | 800 |

Note: The specifications are subject to change without pnor notice.

Performance & Advantages

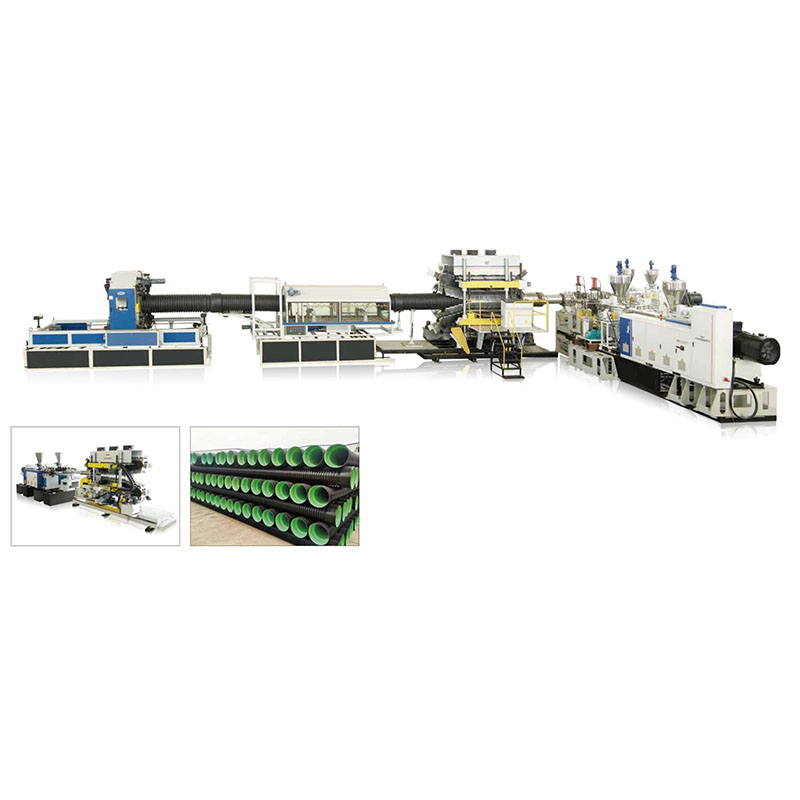

Suzhou Jwell introduced European advanced technology and newly developed parallel-parallel twin screw extruder HDPE/PP DWC pipe line, which has the following characteristics:

1. Adopt two parallel twin-screw extruders, and the mixing effect is excellent. It is possible to use both powdered and granular raw materials at the same time without the need for granulation and low raw material costs.

2. The extruder is equipped with a side feeding system, which can adjust the calcium powder filling ratio at any time online, and the formula exchange is convenient.

3. Extruder has vacuum vents. To make the inner and outer walls of the pipe dense and smooth without bubbles.

4. The screw & barrel are building block type. maintenance and replacement easily.

HDPE Corrugated Pipes are used in sewerage projects in industrial waste transport in storm water drainage and in transport of the drainage waters.

A- HDPE Corrugated Pipes – Double Wall Corrugated Pipes:

HDPE Corrugated Double Wall Pipes are produced as SN 2, SN 4, SN 6 and SN 8 as their corrugated pipe diameter table. Corrugated Pipes outer surface of the corrugated and the smooth inner surface of the double-walled and because produced from HDPE have high resistance against corrosion. Uses of the HDPE Corrugated Double Wall Pipes, drainage projects produces as Perforated Corrugated Pipe and Corrugated Pipe. Use of Corrugated pipe minimum life of 50 years and when used in accordance with the SN value of the project and can be use more years accurate by using appropriate methods.

Double Wall Corrugated Pipes used in sewerage projects, industrial waste transportation, storm water drainage and drainage waters transportation project. Corrugated Pipe thanks to its flexible structure demonstrate compliance with the underground motion. Corrugated Pipes provide many years of trouble-free operation in infrastructure projects. Corrugated pipes ensures a longer life of the filling being laid solid ground.

Corrugated Pipes have superior corrosion resistance, provide ease transportation because of lightness. By combining the floor seals are completed quickly. Due to the sealing properties do not spread sewage into the groundwater. Corrugated Pipes are usually produced in 6 m lengths.

Fields of Use

HDPE Double Wall Corrugated Pipes are mainly used in:

● Drainage projects.

● Sewage pipeline projects.

● Storm water discharge projects.

● Sub-roadway waste water carriage projects.

● Power cable protection projects.

● Waste water discharge pipeline projects and storm water discharge projects as perforated pipe – slotted pipe.

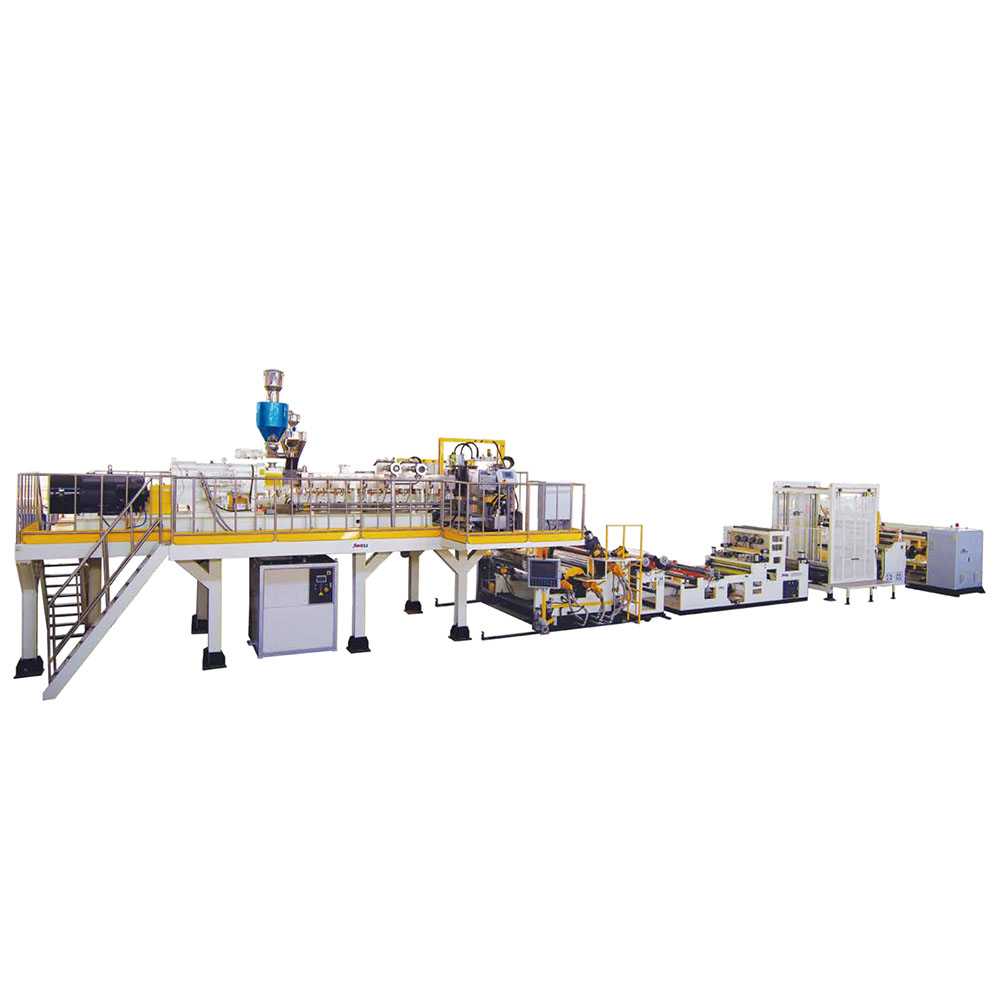

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of regard the market, regard the custom, regard the science and the theory of quality the basic, belief the very first and management the advanced for High definition Pipe Extrusion Process - Parallel/Conical Twin Screw HDPE/PP/PVC DWC Pipe Extrusion Line – JWELL , The product will supply to all over the world, such as: Jamaica, luzern, Irish, With many years good service and development, we have a qualified international trade sales team. Our goods have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.