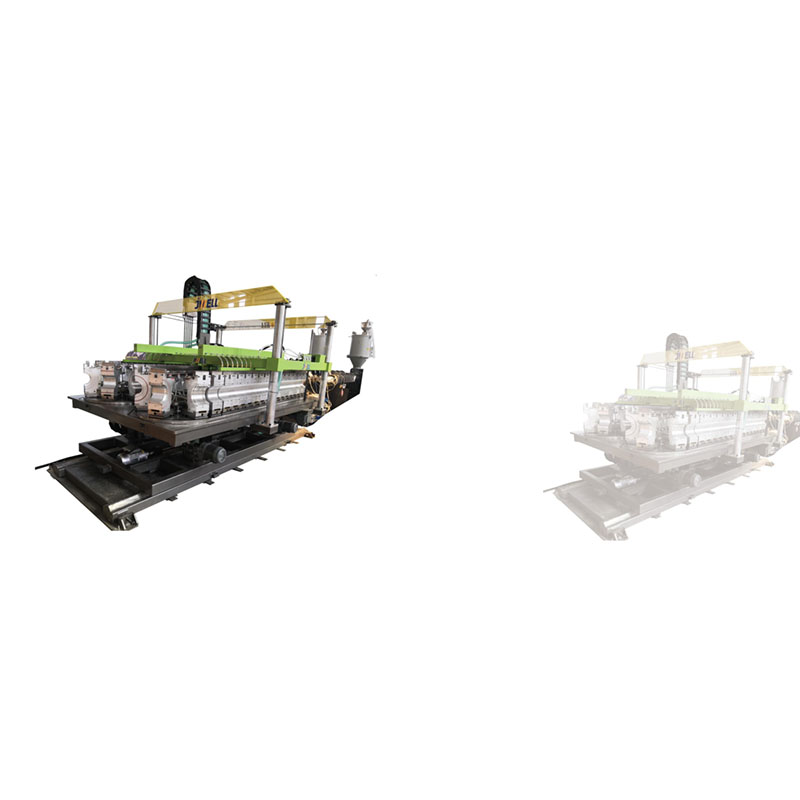

Low MOQ for Extrusion Pipe Process - Opened Water Cooling HDPE/PP/PVC DWC Pipe Extrusion Line – JWELL

Low MOQ for Extrusion Pipe Process - Opened Water Cooling HDPE/PP/PVC DWC Pipe Extrusion Line – JWELL Detail:

Main Technical Parameter

● Sizing sleeve is made of aluminum alloy, and the surface ts wear-resistant. The tube waveform can be calculated by special softv/are program, and the ring stiffness can be obtained at the same weight.

● Cooling water is injected at both forming and return sections (such models in the market are air-cooled and without water).

● The mokimg machine has special structure to effectively reduce the dislocation of ape (with patent protection).

● The molding machine has special structure to effectively inhibit the upwarping and ensure that the module will not deform (with patent protection).

● The platform is equipped with guide device, which can realize synchronous access of mold base.

● The stability of vacuum can be improved by the vacuum box of the molding machine

● The molding machine ts equipped with backup power supply, which can ensure the smooch withdrawal of the equipment from the production position in case ol sudden power failure to prevent the locking

● Special structure ol water tray can ensure the high flow cooling water injected into module (with patent projection).

● The movement of lower frame and upper frame are all electrically adjusted.

● in addition to single screw extruder, tapered twin screw extruder and parallel twin screw extruder can be used c the production line All three kinds of extruders are produced by JWELL. with precise electronic control, good plasticizing and stable operation. Mich can meet the needs of different customers.

| Type | Pipe Size | Speed | Total Power | Product Line length and width |

| JWBWK-400 | ID100 – 400 | Max3.5 | 265 | 30×4 |

| JWBWK-500 | ID200 – 500 | Max3.5 | 280 | 30×4 |

HDPE Corrugated Pipes mainly have 2 types

A- HDPE Corrugated Pipes – Double Wall Corrugated Pipes:

HDPE Corrugated Double Wall Pipes are produced as SN 2, SN 4, SN 6 and SN 8 as their corrugated pipe diameter table. Corrugated Pipes outer surface of the corrugated and the smooth inner surface of the double-walled and because produced from HDPE have high resistance against corrosion. Uses of the HDPE Corrugated Double Wall Pipes, drainage projects produces as Perforated Corrugated Pipe and Corrugated Pipe. Use of Corrugated pipe minimum life of 50 years and when used in accordance with the SN value of the project and can be use more years accurate by using appropriate methods.

Double Wall Corrugated Pipes used in sewerage projects, industrial waste transportation, storm water drainage and drainage waters transportation project. Corrugated Pipe thanks to its flexible structure demonstrate compliance with the underground motion. Corrugated Pipes provide many years of trouble-free operation in infrastructure projects. Corrugated pipes ensures a longer life of the filling being laid solid ground.

Corrugated Pipes have superior corrosion resistance, provide ease transportation because of lightness. By combining the floor seals are completed quickly. Due to the sealing properties do not spread sewage into the groundwater. Corrugated Pipes are usually produced in 6 m lengths.

Fields of Use

HDPE Double Wall Corrugated Pipes are mainly used in:

● Drainage projects.

● Sewage pipeline projects.

● Storm water discharge projects.

● Sub-roadway waste water carriage projects.

● Power cable protection projects.

● Waste water discharge pipeline projects and storm water discharge projects as perforated pipe – slotted pipe.

Product detail pictures:

Related Product Guide:

We'll make each hard work to become excellent and excellent, and speed up our measures for standing from the rank of intercontinental top-grade and high-tech enterprises for Low MOQ for Extrusion Pipe Process - Opened Water Cooling HDPE/PP/PVC DWC Pipe Extrusion Line – JWELL , The product will supply to all over the world, such as: Riyadh, Angola, Melbourne, We have to continue to uphold the quality, comprehensive, efficient business philosophy of honest, responsible, innovativespirit of service, abide by the contract and abide by reputation, first-class products and improve service welcome overseas customers patrons.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.