Low MOQ for Extrusion Pipe Process - Three Layer PVC Pipe Co-extrusion line – JWELL

Low MOQ for Extrusion Pipe Process - Three Layer PVC Pipe Co-extrusion line – JWELL Detail:

Main Technical Parameter

| Type | Pipe spec (mm) | Extruder | Main Power(kw) | Output (kg/h) |

| JWG-PVC250 Three-layer | ø75-ø250 | SJZ65/132+55/110 | 37+22 | 300-400 |

| JWG-PVC450 Three-layer | ø200 – ø450 | SJZ80/1564+65/132 | 55+37 | 400-600 |

| JWG-PVC630 Three-layer | ø315-ø630 | SJZ92/188+65/132 | 110+37 | 740-900 |

Note:The specifications are subject to change without prior notice.

Performance & Advantages

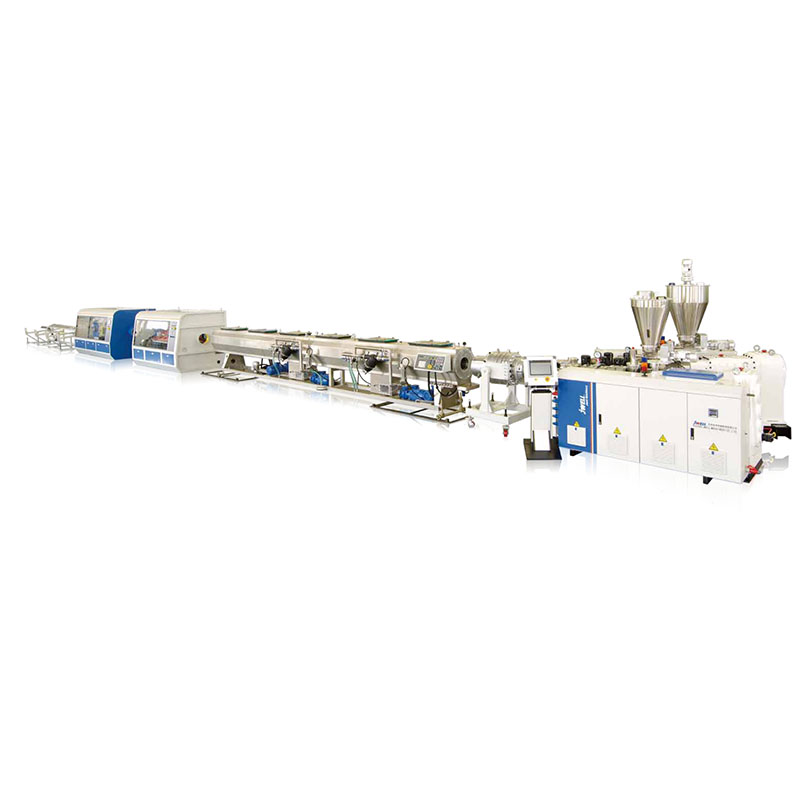

1. The extruder uses super wear-resistant alloy screw barrel; the twin-screw feeds evenly and the powder doesn’t bridge.

2. Optimized design of PVC three-layer mold, the internal flow channel is chrome-plated and highly polished, wear and corrosion resistant; with special sizing sleeve, the pipe product has high speed and good surface.

3. Cutting machine adopts rotating clamping device to adapt to different pipe diameters, eliminating the trouble of frequent replacement of fixtures. Equipped with a new type of adjustable floating chamfering mechanism, the size of chamfer can be adjusted according to the pipe diameter and wall thickness, cutting and chamfering can be performed in one step. Closed suction device, better chip suction effect.

PVC pipe is plastic pipe made from the thermoplastic material polyvinyl chloride (PVC). PVC pipe is commonly used across applications and industries and comes in different types. PVC piping is often used in drainage, water supply, irrigation, chemical handling, vent tubing, duct work and waste management plumbing supply applications. Available PVC plumbing supply products are schedule 40 PVC, schedule 80 PVC, furniture grade PVC pipe, CPVC pipe, drain waste vent (DWV) pipe, flex pipe, clear PVC pipe and double containment pipe.

Schedule 40 and schedule 80 pipe are versatile piping certified and registered per industry codes and standards for today’s many uses. Furniture grade PVC pipe is available in different colors without markings or labels and features a clean, glossy finish. DWV piping is used for structural handling of waste materials. Flex pipe is flexible PVC pipe for applications where rigid pipe is not suitable or useful. Clear piping allows visual monitoring of fluid flow and pipe quality. Double containment pipe is designed to meet industry regulations to capture system leaks or failures for improving safety or when it is required.

PVC pipe is available in sizes that range from 1/8 inch up to 24 inches in diameter. Some of the most common sizes are ½ inch, 1 ½ inch, 3 inch, 4 inch, 6 inch, 8 inch and 10 inch PVC pipe. PVC piping is shipped in standard 10 foot or 20 foot length sections. This saves on overall handling costs and allows offering lower priced products. We have 5 foot sections of SCH 40 PVC, SCH 80 PVC and furniture PVC exclusively available for shipping ground.

When PVC is used to refer to plastic pipe, it is typically understood to be uPVC (unplasticized PVC) by design. uPVC pipe is rigid plastic pipe and is the most common form of PVC piping used in construction applications. uPVC pipes are manufactured without plasticizing agents that can be added to make the PVC material more flexible. Flex pipe is an example of plasticized PVC due to its hose-like flexibility.

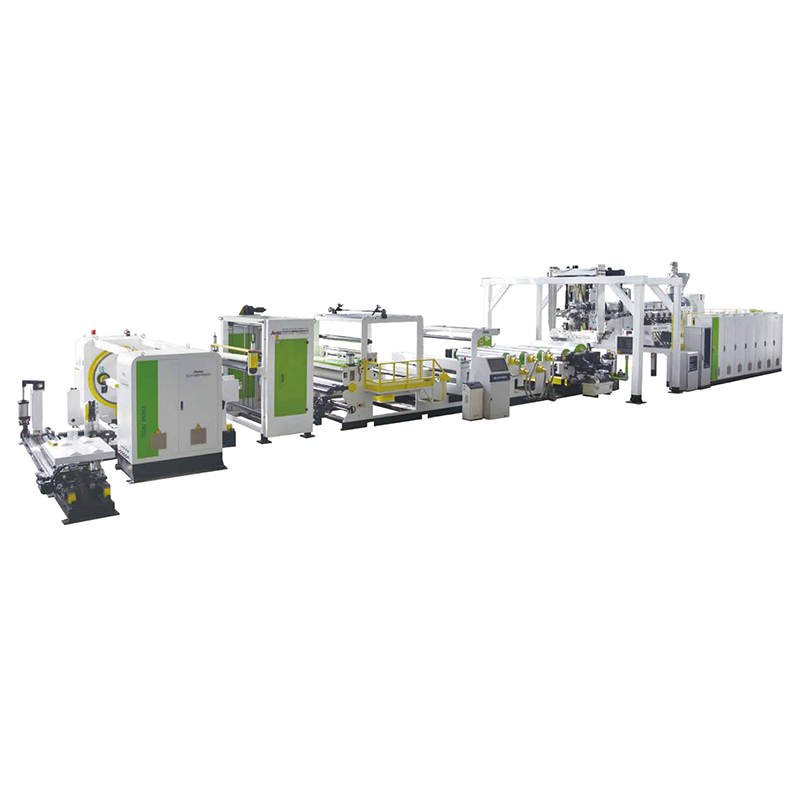

Product detail pictures:

Related Product Guide:

Our firm aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine regularly for Low MOQ for Extrusion Pipe Process - Three Layer PVC Pipe Co-extrusion line – JWELL , The product will supply to all over the world, such as: Niger, Haiti, Chile, Be sure to feel cost-free to send us your specs and we are going to respond for you asap. We have got a experienced engineering team to serve for the every single comprehensive needs. Free samples may be sent for yourself personally to know far more facts. So that you can meet your desires, please actually feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.