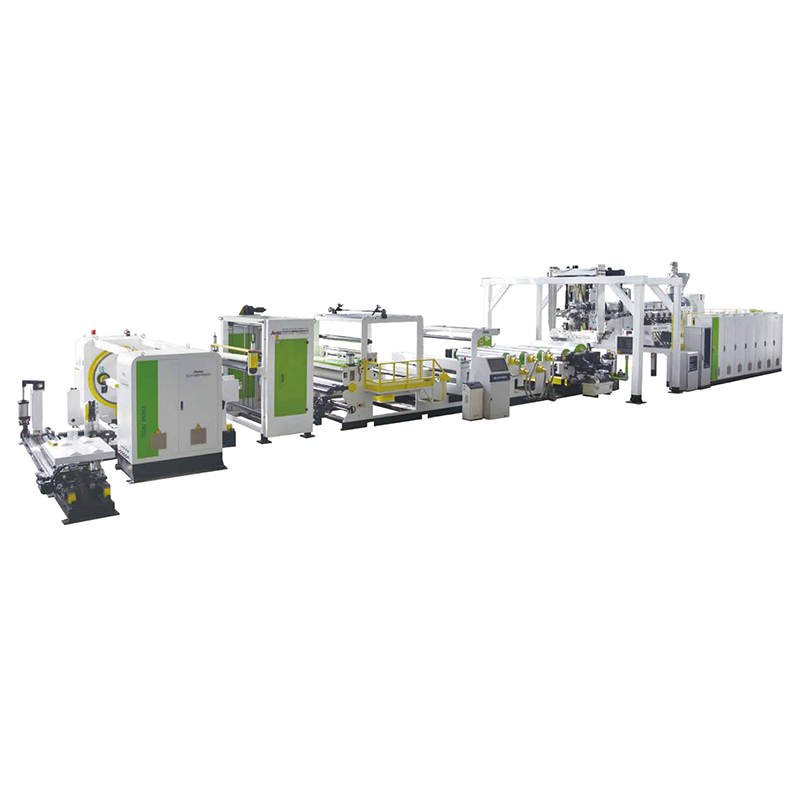

OEM manufacturer Plastic Sheet Extruder - EVA/POE Solar Film Extrusion Line – JWELL

OEM manufacturer Plastic Sheet Extruder - EVA/POE Solar Film Extrusion Line – JWELL Detail:

Main Technical Parameter

| Model | Extruder type | Products thickness(mm) | Max. output |

| Single extrusion | JWS200 | 0.2-1.0 | 500-600 |

| Co-extrusion | JWS160+JWS180 | 0.2-1.0 | 750-850 |

| Co-extrusion | JWS180+JWS180 | 0.2-1.0 | 800-1000 |

| Co-extrusion | JWS180+JWS200 | 0.2-1.0 | 900-1100 |

Note: The specifications are subject to change without prior notice.

Product Description

The advantages of solar cell encapsulation film (EVA) are summarized as follows:

1. High transparency and high adhesion can be applied to various interfaces, including glass, metal and plastics such as PET.

2. Good durability can resist high temperature, moisture, ultraviolet rays and so on.

3. Easy to store. Stored at room temperature, the adhesion of EVA is not affected by humidity and absorbent films.

4. Compared with PVB, it has stronger sound insulation effect, especially for high frequency sound effects.

5. Low melting point, easy to flow, suitable for laminating process of various glass, such as patterned glass, tempered glass, curved glass, etc.

The EVA film is used as the laminated glass, which fully complies with the national standard “GB9962-99″ for laminated glass. The following is an example of a 0.38mm thick transparent film.

The performance indicators are as follows:

| Project Indicator | |

| Tensile strength (MPa) | ≥17 |

| Visible light transmittance (%) | ≥87 |

| Elongation at break (%) | ≥650 |

| Fog rate (%) | 0.6 |

| Bonding strength (kg/cm) | ≥2 |

| Radiation resistance qualified | |

| Water absorption (%) | ≤0.15 |

| Heat resistance pass | |

| Moisture resistance qualified | |

| Impact resistance qualified | |

| Shot bag impact performance Qualified | |

| UV cutoff rate | 98.50% |

What are the advantages and disadvantages of EVA packaging film?

The main component of EVA film is EVA, plus various additives, such as cross-linking agent, thickener, antioxidant, light stabilizer, etc. EVA has become the preferred material for photovoltaic module packaging before 2014 due to its excellent packaging performance, good aging resistance and low price. But its PID defect is also obvious.

The emergence of double-glass modules seems to give EVA the possibility to overcome inherent defects. Since the water vapor transmission rate of glass is almost zero, the low water permeability or zero water permeability of double-glass modules makes EVA hydrolysis resistance no longer a problem.

Opportunities and challenges of POE packaging films

Developed from metallocene catalysts, POE is a new type of polyolefin thermoplastic elastomer with narrow relative molecular mass distribution, narrow comonomer distribution and controllable structure. POE has excellent water vapor barrier ability and ion barrier ability. The water vapor transmission rate is only about 1/8 of EVA, and the aging process does not produce acidic substances. It has excellent anti-aging performance and is a high-efficiency and high-reliability photovoltaic. The material of choice for component encapsulation films.

Automatic gravimetric feeding system makes sure variety of solid, liquid additives and raw materials high-precision feeding. Low-temperature extrusion systems to ensure adequate mixing in the premise of plastification to prevent cross-linking additives. Special design of Casting part give the perfect solution to roller adhibition and water spalling. Special online tempering device to get rid of inner stress. Tension control system ensure the flexible sheets conveying placidly during cooling , pulling and winding process.The on-line thickness measuring and defect inspecting system can provide real-time feedback of the production quality of EVA/POE solar film.

EVA/POE photovoltaic film is mainly used in the encapsulation of photovoltaic modules and is the key material of photovoltaic modules; It can also be used in various industries such as architectural glass curtain wall, automotive glass, hot melt adhesive, etc.

Product detail pictures:

Related Product Guide:

We consistently carry out our spirit of Innovation bringing development, Highly-quality ensuring subsistence, Management promoting benefit, Credit attracting customers for OEM manufacturer Plastic Sheet Extruder - EVA/POE Solar Film Extrusion Line – JWELL , The product will supply to all over the world, such as: Melbourne, Turin, Moldova, Our staffs are adhering to the Integrity-based and Interactive Development spirit, and the tenet of First-class Quality with Excellent Service. According to the needs of every customer, we give customized & personalised services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.