Plastic Pipe Extrusion

-

Large Diameter HDPE Pipe Extrusion Line

Performance & Advantages: Extruder is JWS-H series High efficiency, high output single screw extruder. The special screw barrel structure design ensures ideal melt uniformity at lower solution temperatures. Designed for large-diameter pipe extrusion, the spiral distribution structure mold is equipped with an in-mold suction pipe internal cooling system. Combined with a special low-sag material, it can produce ultra-thick-walled, large-diameter pipes. Hydraulic opening and closing two-stage vacuum tank, computerized centralized control and coordination of multiple crawler tractors, chipless cutter and all units, a high degree of automation. The optional wire rope tractor can make the initial operation of the large-caliber tube more convenient.

-

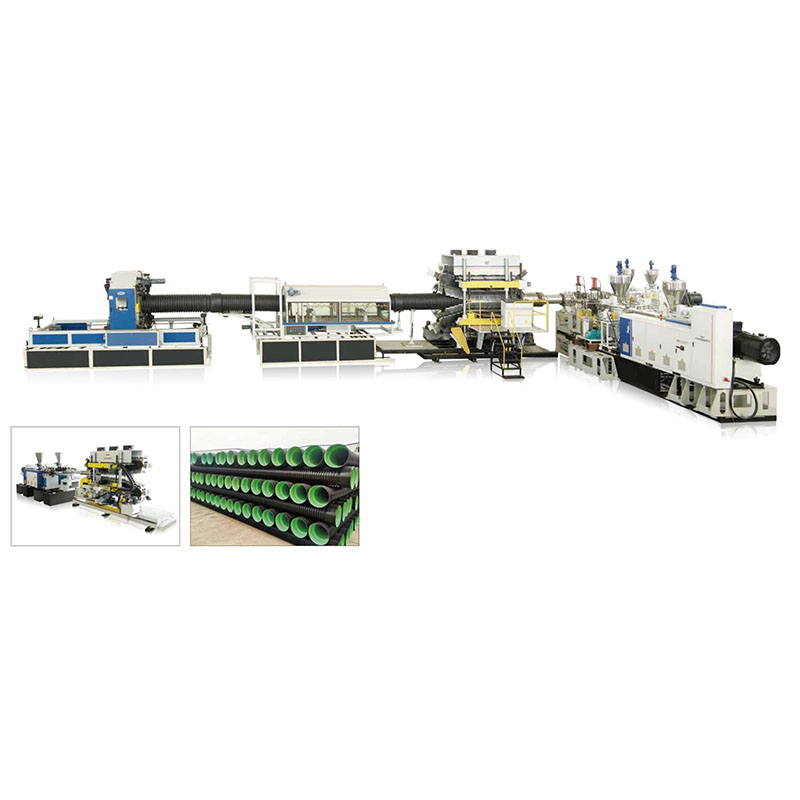

Parallel/Conical Twin Screw HDPE/PP/PVC DWC Pipe Extrusion Line

Suzhou Jwell introduced European advanced technology and newly developed parallel-parallel twin screw extruder HDPE/PP DWC pipe line.

-

Multi-layer HDPE Pipe Co-extrusion Line

According to the special needs of users, we can provide 2-layer / 3-layer / 5-layer and multilayer solid wall pipe line. Multiple extruders can be synchronized, and multiple meter weight control system can be selected. can be centralize controlled in a main PLC to achieve precise and quantitative extrusion of each extruder. According to the multi-layer spiral mold designed with different layers and thickness ratios, the distribution of mold cavity flow channels is reasonable to ensure that the tube layer thickness is uniform and the plasticization effect of each layer is better.

-

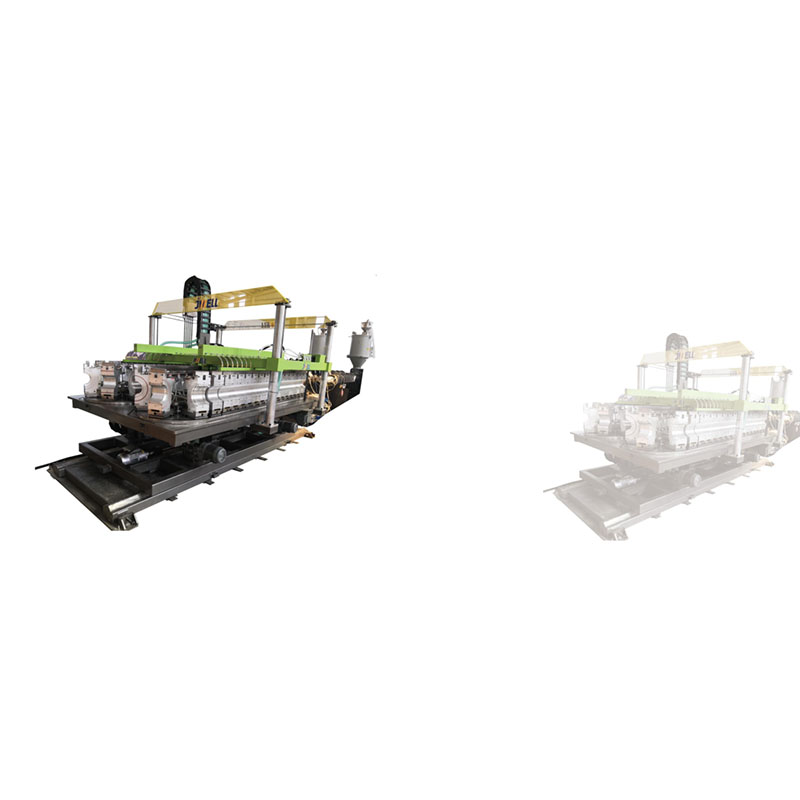

Pressured Water Cooling HDPE/PP/PVC DWC Pipe Extrusion Line

HDPE Corrugated Pipes are used in sewerage projects in industrial waste transport in storm water drainage and in transport of the drainage waters.

-

HDPE Heat Insulation Pipe Extrusion Line

PE insulation pipe is also called PE outer protection pipe, jacket pipe, sleeve pipe. The direct buried polyurethane insulation pipe is made of HDPE insulation pipe as the outer protective layer, the middle filled polyurethane rigid foam is used as the insulation material layer, and the inner layer is steel pipe. Polyure-thane direct buried insulation pipe has good mechanical properties and thermal insulation performance. Under normal circumstances, it can withstand high temperature of 120-180 °C, and is suitable for various cold and hot water high and low temperature pipeline insulation projects.

-

Opened Water Cooling HDPE/PP/PVC DWC Pipe Extrusion Line

HDPE Corrugated Pipes are used in sewerage projects in industrial waste transport in storm water drainage and in transport of the drainage waters.

-

High-speed Energy-saving MPP Pipe Extrusion Line

The non-excavation modified polypropylene (MPP) pipe for power cables is a new type of plastic pipe made of modified polypropylene as the main raw material, using a special formula and processing technology. It has high strength, good stability, and easy cable placement. Simple construction, cost-saving and a series of advantages. As a pipe jacking construction, it highlights the personality of the product. It meets the development requirements of modern cities and is suitable for burying in the range of 2-18M. The construction of the modified MPP power cable sheath using trenchless technology not only ensures the reliability of the pipe network, reduces the failure rate of the pipe network, but also greatly improves the city appearance and environment.

-

Small Sized HDPE/PPR/PE-RT/PA Pipe Extrusion Line

The main screw adopts BM high-efficiency type, and the output is fast and plasticized well.

The wall thickness of pipe products is precisely controlled and very less waste of raw materials.

Tubular extrusion special mold, water film high-speed sizing sleeve, equipped with integrated flow control valve with scale.

-

Silicon Coating Pipe Extrusion Line

The raw material of the silicon core tube substrate is high-density polyethylene, the inner layer used a lowest friction coefficient silica gel solid lubricant. It is corrosion resistance, smooth inner wall, convenient gas blowing cable transmission, and low construction cost. According to the needs, different sizes and colors of small tubes are concentrated by external casing. The products are applied to optical cable communication network system for freeway, railway and so on.

-

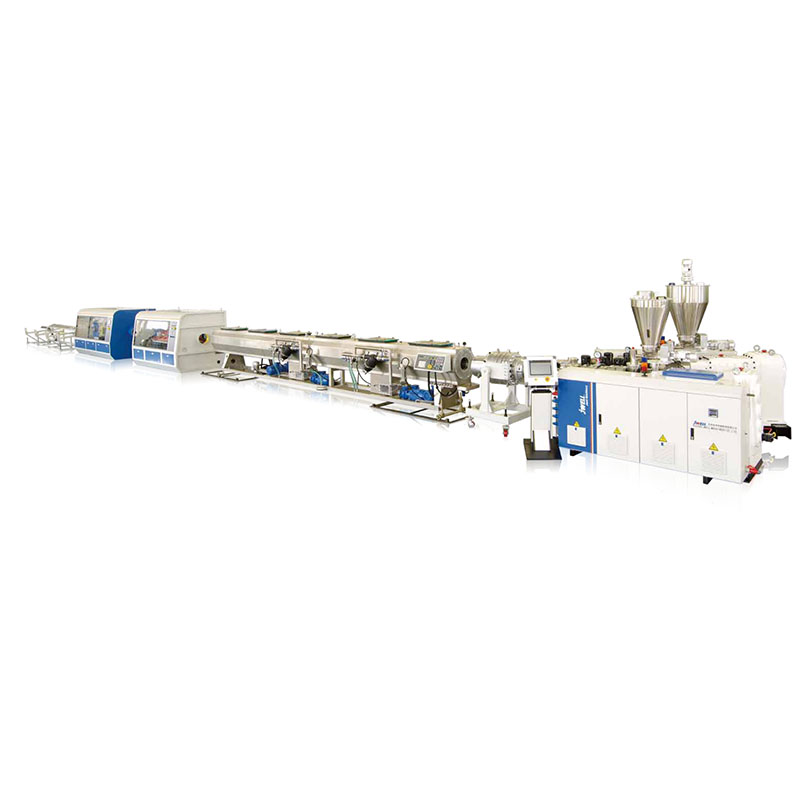

PVC-UH/UPVC/CPVC Pipe Extrusion Line

A variety of specifications and models of PVC twin-screw extruder can produce pipes of different diameters and different wall thicknesses. Specially designed screw structure with uniform plasticization and high output. Extrusion molds made of high quality alloy steel, internal flow channel chrome plating, polishing treatment, wear and corrosion resistance; with a dedicated high-speed sizing sleeve, pipe surface quality is good. The special cutter for PVC pipe adopts a rotating clamping device, which does not require replacing the fixture with different pipe diameters. With chamfering device, cutting, chamfering, one-step molding. Support optional online belling machine.

-

Three Layer PVC Pipe Co-extrusion line

Use two or more SJZ series conical twin screw extruder to implement co-extruded three-layer PVC pipe. The sandwich layer of the pipe is high-calcium PVC or PVC foam raw material.

-

PVC Dual Pipe Extrusion Line

Corresponding to the different requirements of pipe diameter and output, there are two types of SJZ80 and SJZ65 special twin-screw extruders optional; the dual pipe die evenly distributes the material output, and the pipe extrusion speed is quickly plasticized. High-efficiency double-vacuum cooling box can be controlled separately, and the adjustment operation is convenient in the production process. Dustless cutting machine, double station independent control, fast speed, accurate cutting length. Pneumatically rotating clamps eliminates the need to change clamps. With chamfering device optional.