Plastic Pipe Extrusion

-

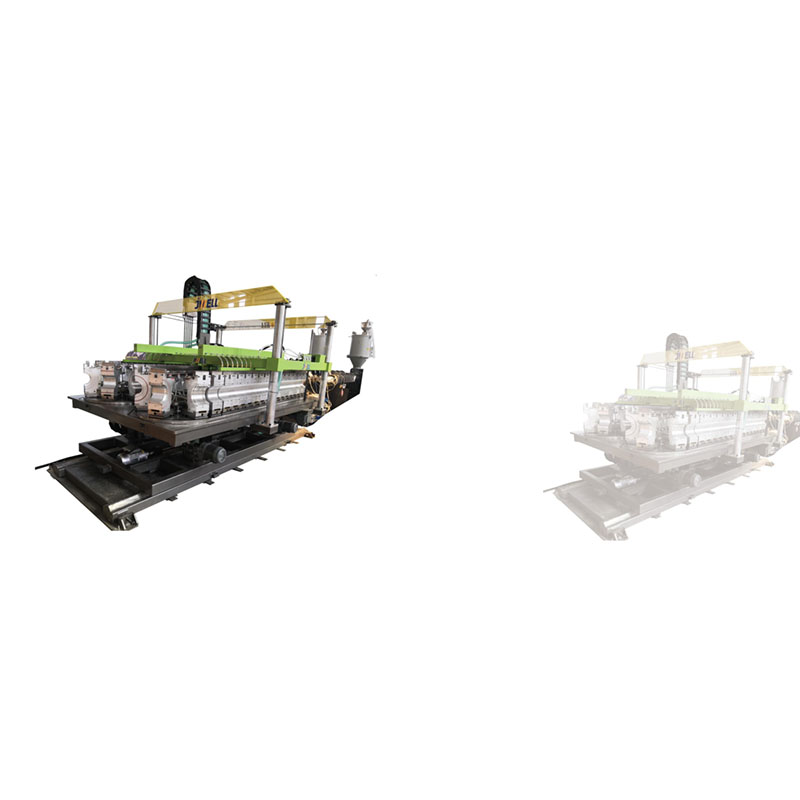

Opened Water Cooling HDPE/PP/PVC DWC Pipe Extrusion Line

HDPE Corrugated Pipes are used in sewerage projects in industrial waste transport in storm water drainage and in transport of the drainage waters.

-

High-speed Energy-saving MPP Pipe Extrusion Line

The non-excavation modified polypropylene (MPP) pipe for power cables is a new type of plastic pipe made of modified polypropylene as the main raw material, using a special formula and processing technology. It has high strength, good stability, and easy cable placement. Simple construction, cost-saving and a series of advantages. As a pipe jacking construction, it highlights the personality of the product. It meets the development requirements of modern cities and is suitable for burying in the range of 2-18M. The construction of the modified MPP power cable sheath using trenchless technology not only ensures the reliability of the pipe network, reduces the failure rate of the pipe network, but also greatly improves the city appearance and environment.

-

Small Sized HDPE/PPR/PE-RT/PA Pipe Extrusion Line

The main screw adopts BM high-efficiency type, and the output is fast and plasticized well.

The wall thickness of pipe products is precisely controlled and very less waste of raw materials.

Tubular extrusion special mold, water film high-speed sizing sleeve, equipped with integrated flow control valve with scale.