Products

-

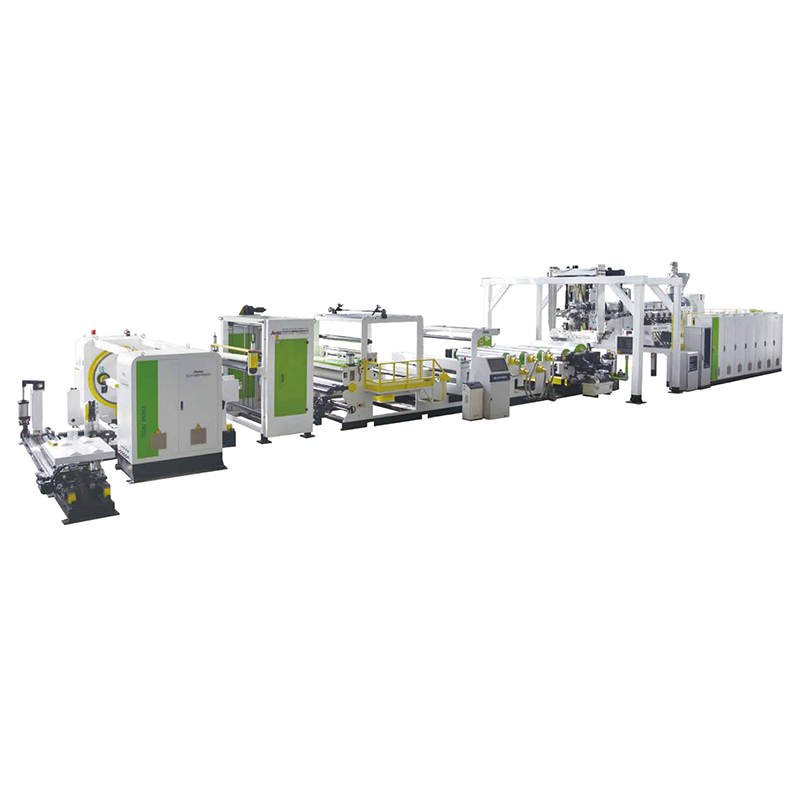

AUTOMATlC PULP MOLDlNG FlNERY TABLEWARE PRODUCTlON LlNE

Suitable for knife, fork, spoon and fine tableware

package and other high value-added pulp molding products.

Suitable for the full range of tableware package products with large capacity demand.

-

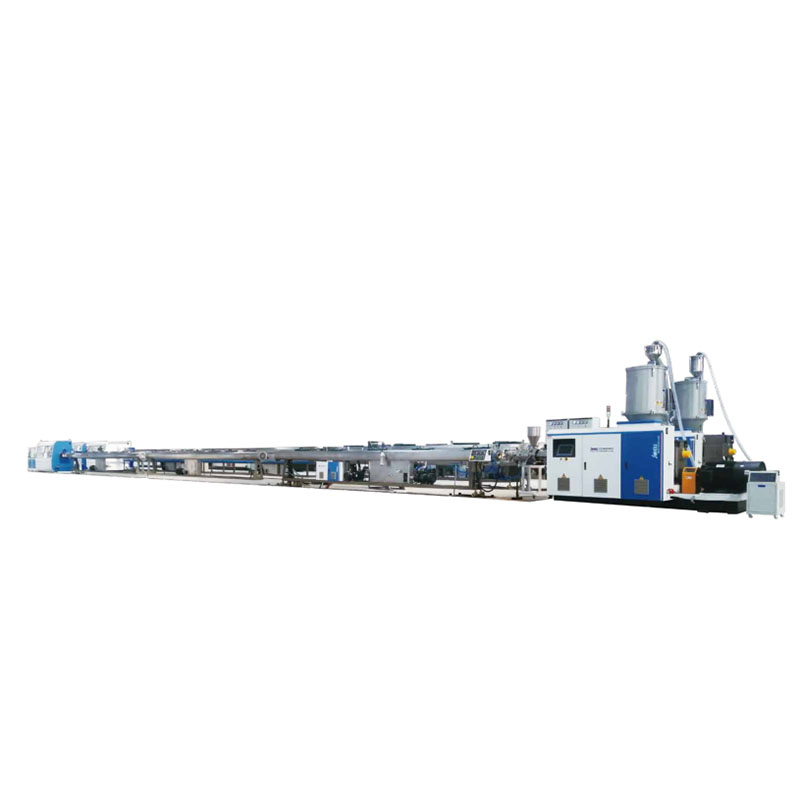

Large Diameter HDPE Pipe Extrusion Line

Performance & Advantages: Extruder is JWS-H series High efficiency, high output single screw extruder. The special screw barrel structure design ensures ideal melt uniformity at lower solution temperatures. Designed for large-diameter pipe extrusion, the spiral distribution structure mold is equipped with an in-mold suction pipe internal cooling system. Combined with a special low-sag material, it can produce ultra-thick-walled, large-diameter pipes. Hydraulic opening and closing two-stage vacuum tank, computerized centralized control and coordination of multiple crawler tractors, chipless cutter and all units, a high degree of automation. The optional wire rope tractor can make the initial operation of the large-caliber tube more convenient.

-

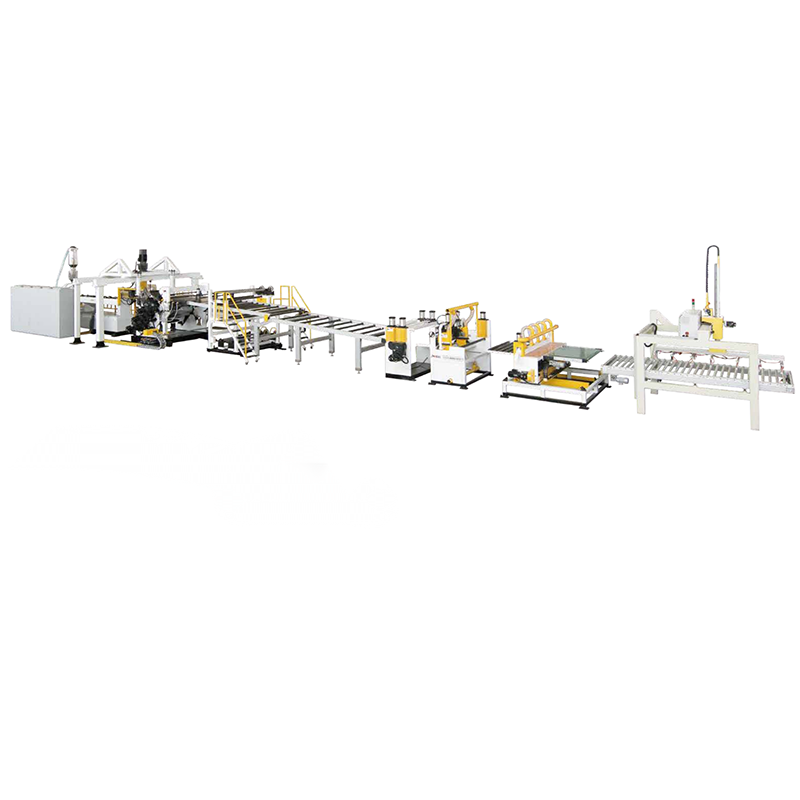

PP/PE Solar Photovoltaic Cell Backsheet Extrusion Line

This production line is used to produce high-performance, innovative fluorine-free solar photovoltaic backsheets that conform to the trend of green manufacturing;

-

High-speed Energy-saving HDPE Pipe Extrusion Line

HDPE pipe is a type of flexible plastic pipe used for fluid and gas transfer and is often used to replace ageing concrete or steel mains pipelines. Made from the thermoplastic HDPE (high-density polyethylene), its high level of impermeability and strong molecular bond make it suitable for high pressure pipelines. HDPE pipe is used across the globe for applications such as water mains, gas mains, sewer mains, slurry transfer lines, rural irrigation, fire system supply lines, electrical and communications conduit, and storm water and drainage pipes.

-

WPC Wall Panel Extrusion Line

The machine is used for pollution WPC decoration product, which is widely used in house and public decoration field, features non-polution,

-

Small Sized HDPE/PPR/PE-RT/PA Pipe Extrusion Line

The main screw adopts BM high-efficiency type, and the output is fast and plasticized well.

The wall thickness of pipe products is precisely controlled and very less waste of raw materials.

Tubular extrusion special mold, water film high-speed sizing sleeve, equipped with integrated flow control valve with scale.

-

PC/PMMA/GPPS/ABS Sheet Extrusion Line

Garden, recreation place, decoration and the corridor pavilion; Internal and external ornaments in the commercial building, curtain wall of the modern urban building;

-

TPU Glass Interlayer Film Extrusion Line

TPU Glass Adhesive Film: As a new type of glass laminated film material, TPU has higher transparency, never yellowing, higher bonding strength to glass and more outstanding cold resistance.

-

PVC Trunking Extrusion Line

PVC trunk is a kind of trunks, which is mainly used for internal wiring routing of electrical equipment. Now, environmentally friendly & flame retardant PVC trunk is widely used.

-

Silicon Coating Pipe Extrusion Line

The raw material of the silicon core tube substrate is high-density polyethylene, the inner layer used a lowest friction coefficient silica gel solid lubricant. It is corrosion resistance, smooth inner wall, convenient gas blowing cable transmission, and low construction cost. According to the needs, different sizes and colors of small tubes are concentrated by external casing. The products are applied to optical cable communication network system for freeway, railway and so on.

-

PP/PE/ABS/PVC Thick Board Extrusion Line

PP thick plate, is an environmentally-friendly product and is widely applied in chemistry industry, food industry, anti-erosion industry, environmentally-friendly equipments industry, etc.

PP thick plate extrusion line of 2000mm width is a newly developed line which is the most advanced and stable line compared with other competitors.

-

TPU Casting Composite Film Extrusion Line

TPU multi-group casting composite material is a kind of material which can realize 3-5 layers of different materials by multi-step casting and online combination. It has beautiful surface and can make different patterns. It has superior strength, wear resistance, safety and environmental protection performance. It is used in inflatable life jacket, diving BC jacket, life raft, hovercraft, inflatable tent, inflatable water bag, military inflatable self expansion mattress, massage air bag, medical protection, industrial conveyor belt and professional waterproof backpack.