Products

-

PVC Foaming Board Extrusion Line

PVC foam board also named Snow board and Andy board, the chemical component is polyvinyl chloride, also can be named foam polyvinyl chloride board. PVC Semi-Skinning foam manufacturing technique is combine free foam technique and semi-skinning foam to develop new technology, this equipment have advanced structure,simple formulation,easy operation etc.

-

PVC High Speed Profile Extrusion Line

This line features stable plasticization, high output,low sheering force,long life service and other advantages. The production line consists of control system, conical twin screw extruder or parallel twin screw extruder,extrusion die, calibration unit,haul off unit, film covering machine and stacker.

-

HDPE Heat Insulation Pipe Extrusion Line

PE insulation pipe is also called PE outer protection pipe, jacket pipe, sleeve pipe. The direct buried polyurethane insulation pipe is made of HDPE insulation pipe as the outer protective layer, the middle filled polyurethane rigid foam is used as the insulation material layer, and the inner layer is steel pipe. Polyure-thane direct buried insulation pipe has good mechanical properties and thermal insulation performance. Under normal circumstances, it can withstand high temperature of 120-180 °C, and is suitable for various cold and hot water high and low temperature pipeline insulation projects.

-

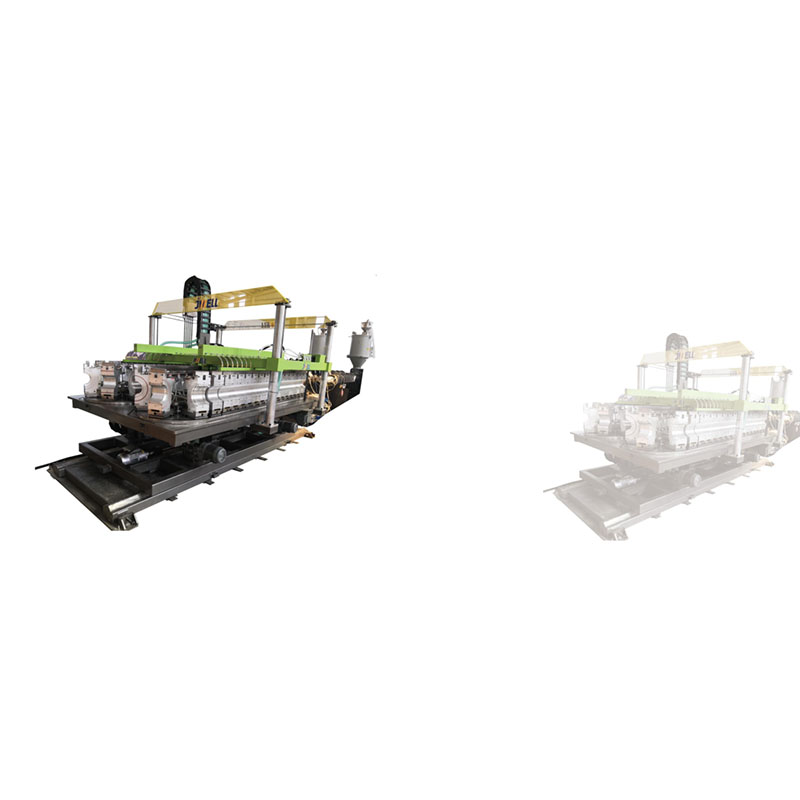

LFT/CFP/FRP/CFRT Continuous Fiber Reinforced

Continuous fiber reinforced composite material is made of reinforced fiber material: glass fiber(GF), carbon fiber(CF), aramid fiber(AF), ultra high molecular polyethylene fiber(UHMW-PE), basalt fiber(BF) by using special process technology to makes high strength continuous fiber and thermal plastic&thermosetting resin soak with each other.

-

Opened Water Cooling HDPE/PP/PVC DWC Pipe Extrusion Line

HDPE Corrugated Pipes are used in sewerage projects in industrial waste transport in storm water drainage and in transport of the drainage waters.

-

PVC Roofing Extrusion Line

● The fire protection performance is remarkable, difficult to burn. Anti-corossion, Acidproof, alkali, radiates quickly, high light- ing, logn life-span. ● Adopt special technology, bears the outdoor atmospheric insolation,the heat insulation performance is good, in the hot summer can provide compares the metal to use a tile more comfortable environment.

-

WPC Door Frame Extrusion Line

The production line can produce the PVC wood-plastic door of the width between 600 and 1200 .the device has SJZ92/188 conical twin screw extruder, calibration, hall-off unit, cutter, such as stacker

-

High-speed Energy-saving MPP Pipe Extrusion Line

The non-excavation modified polypropylene (MPP) pipe for power cables is a new type of plastic pipe made of modified polypropylene as the main raw material, using a special formula and processing technology. It has high strength, good stability, and easy cable placement. Simple construction, cost-saving and a series of advantages. As a pipe jacking construction, it highlights the personality of the product. It meets the development requirements of modern cities and is suitable for burying in the range of 2-18M. The construction of the modified MPP power cable sheath using trenchless technology not only ensures the reliability of the pipe network, reduces the failure rate of the pipe network, but also greatly improves the city appearance and environment.

-

PP/PS Sheet Extrusion Line

Developed by Jwell company, this line is for producing multi-layer environmental-friendly sheet, which is widely used for vacuum forming, green food container and package, different kinds of food packaging container, such as: salver,bowl, canteen, fruit dish, etc.

-

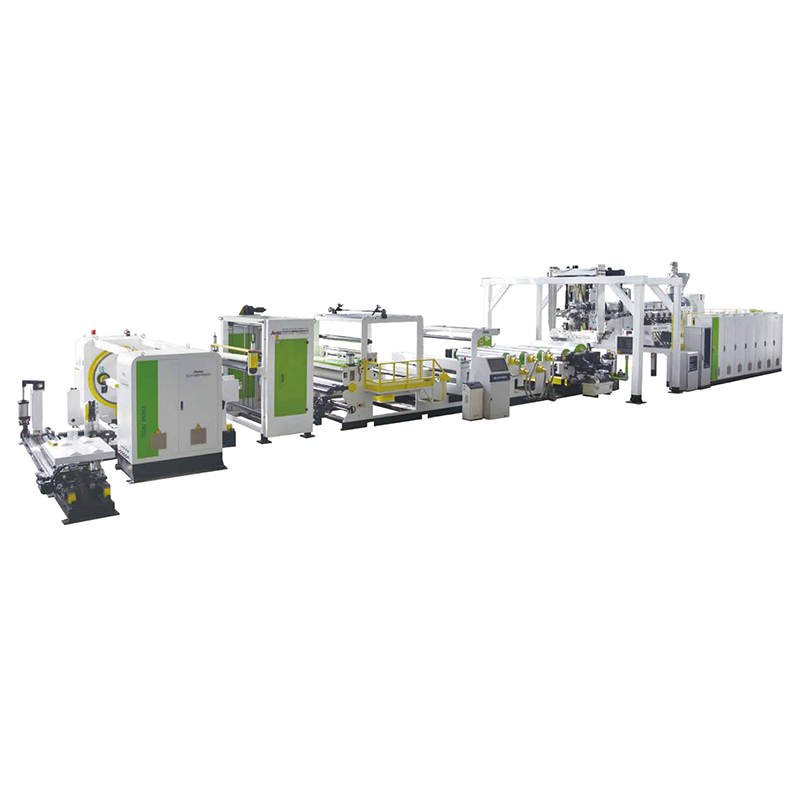

PP/PE Solar Photovoltaic Cell Backsheet Extrusion Line

This production line is used to produce high-performance, innovative fluorine-free solar photovoltaic backsheets that conform to the trend of green manufacturing;

-

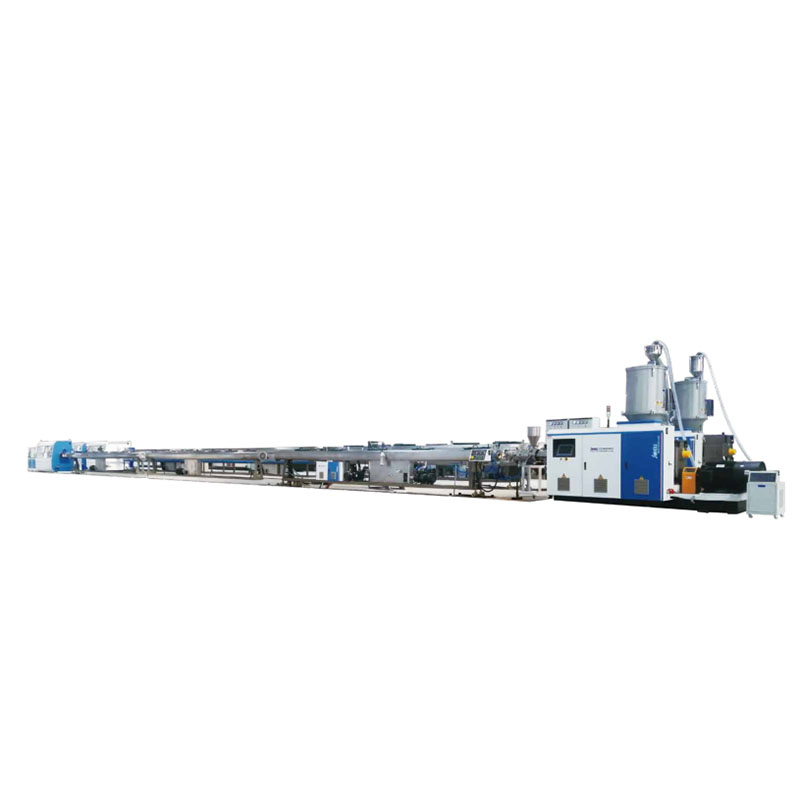

High-speed Energy-saving HDPE Pipe Extrusion Line

HDPE pipe is a type of flexible plastic pipe used for fluid and gas transfer and is often used to replace ageing concrete or steel mains pipelines. Made from the thermoplastic HDPE (high-density polyethylene), its high level of impermeability and strong molecular bond make it suitable for high pressure pipelines. HDPE pipe is used across the globe for applications such as water mains, gas mains, sewer mains, slurry transfer lines, rural irrigation, fire system supply lines, electrical and communications conduit, and storm water and drainage pipes.

-

WPC Wall Panel Extrusion Line

The machine is used for pollution WPC decoration product, which is widely used in house and public decoration field, features non-polution,