Products

-

PP+CaCo3 Outdoor Furniture Extrusion Line

Outdoor furniture applications are increasingly widely, and traditional products are limited by their material itself, such as metal materials are heavy and corrodible, and wooden product are poor in weather resistance, in order to meet the market requirements, our newly developed PP with calcium powder as the main material of the imitation wooden panel products, it have been recognized by the market, and the market prospect is very considerable.

-

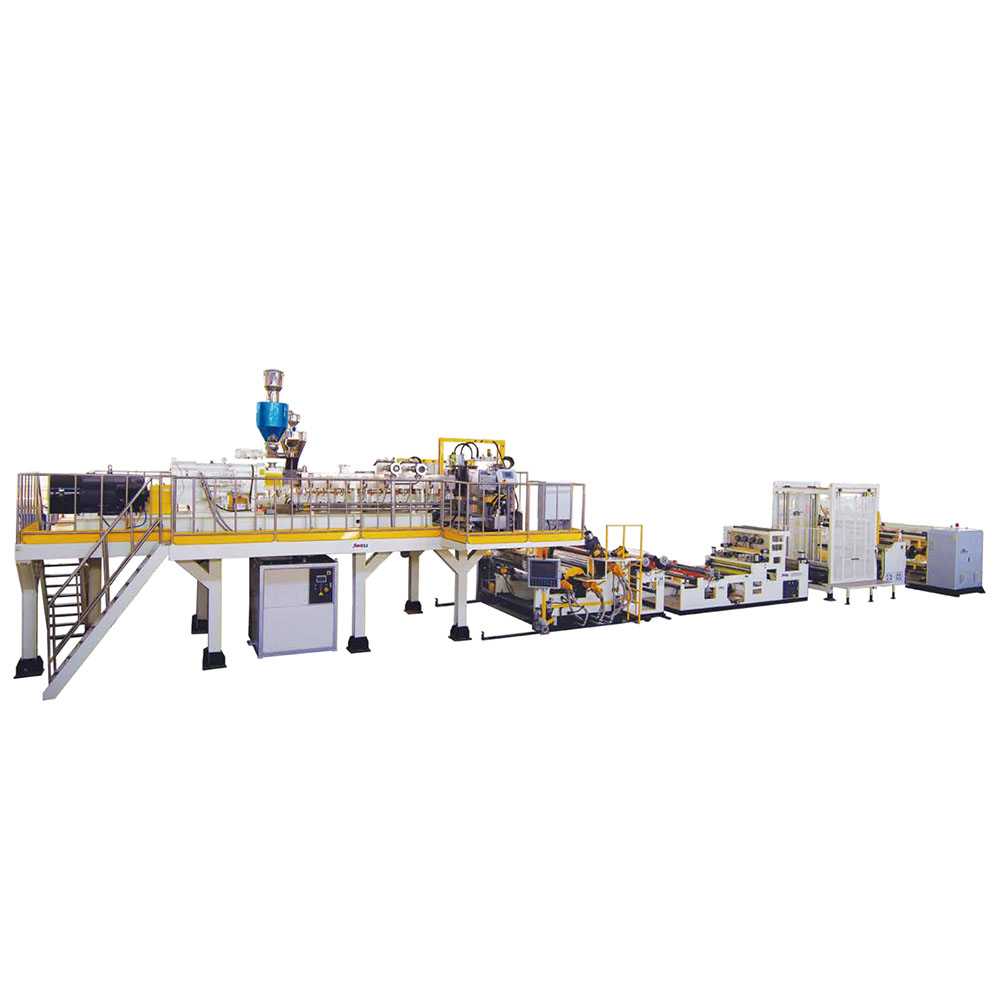

PET/PLA Sheet Extrusion Line

Biodegradable plastic refers to a material that can be degraded into low molecular weight substances by microorganisms themselves or the secretions of microorganisms under certain conditions. The U.S. Food and Drug Administration stipulates that, except for biodegradable plastics and very few water-degradable plastics that can be used in food packaging, other such as photodegradable plastics or light and biodegradable plastics fail to meet the regulations as food packaging materials.

-

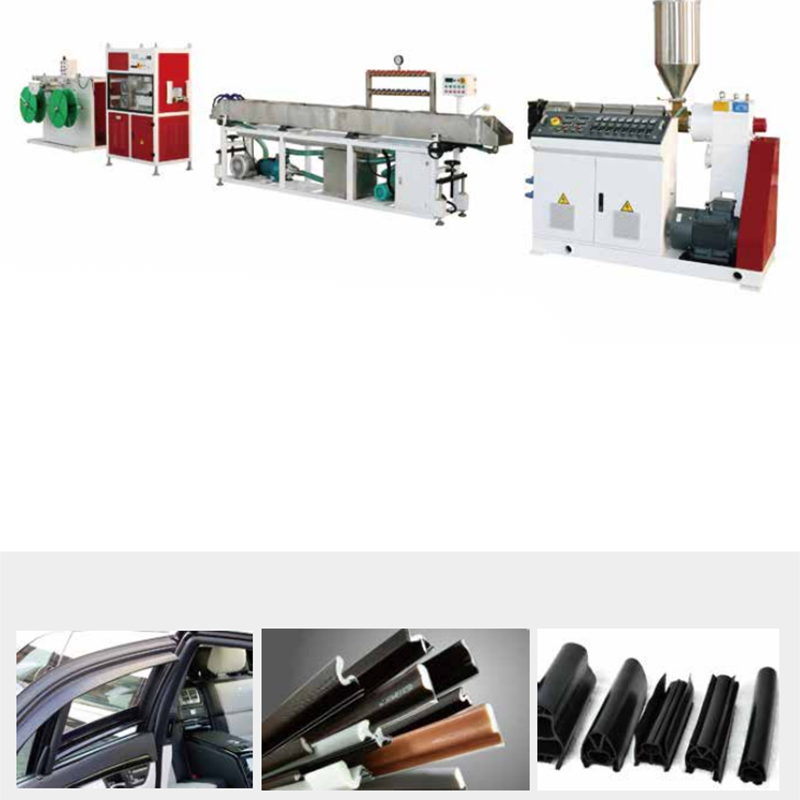

PVC/TPE/TPE Sealing Extrusion Line

The machine is used for producing sealing strip of PVC, TPU, TPE etc material, features high output, steady extrusion,

-

PVC Sheet Extrusion Line

PVC transparent sheet have many advantages of fire-resistance, high quality, low cost, high transparent, good surface, no spot,less water wave, high strike resistance, easy to mould and etc. It is applied to different kinds of packing ,vacuuming and case, such as tools, toys, electronic, food, medicine and clothes.

-

SPC Floor Extrusion Line

SPC Stone plastic extrusion line is PVC as base material and extruded by extruder,then get through four roll calendars,separately put PVC color film layer+PVC wear-resistance layer+PVC base membrane layer to be pressed and pasted together at one time progress.Simple process,complete the paste that depend on heat,without glue. SPC Stone-plastic environmental floor extrusion line advantage

-

Alumium Plastic Composite Panel Extrusion Line

In foreign countries, there are many names of aluminum composite panels, some are called aluminum composite panels (Aluminum Composite Panels); some are called aluminum composite materials (Aluminum Composite Materials); the world’s first aluminum composite panel is named ALUCOBOND.

-

PC/PMMA Optical Sheet Extrusion Line

To meet the demands of market, JWELL supply customer PC PMMA optical sheet extrusion lines with advanced technology, the screws are specially designed according to the rheological property of raw material, precise melt pump system and T-die, which makes the extrusion melt is even and stable and the sheet has excellent optical performance.

-

Pressured Water Cooling HDPE/PP/PVC DWC Pipe Extrusion Line

HDPE Corrugated Pipes are used in sewerage projects in industrial waste transport in storm water drainage and in transport of the drainage waters.

-

PVC Foaming Board Extrusion Line

PVC foam board also named Snow board and Andy board, the chemical component is polyvinyl chloride, also can be named foam polyvinyl chloride board. PVC Semi-Skinning foam manufacturing technique is combine free foam technique and semi-skinning foam to develop new technology, this equipment have advanced structure,simple formulation,easy operation etc.

-

PVC High Speed Profile Extrusion Line

This line features stable plasticization, high output,low sheering force,long life service and other advantages. The production line consists of control system, conical twin screw extruder or parallel twin screw extruder,extrusion die, calibration unit,haul off unit, film covering machine and stacker.

-

High-speed Energy-saving MPP Pipe Extrusion Line

The non-excavation modified polypropylene (MPP) pipe for power cables is a new type of plastic pipe made of modified polypropylene as the main raw material, using a special formula and processing technology. It has high strength, good stability, and easy cable placement. Simple construction, cost-saving and a series of advantages. As a pipe jacking construction, it highlights the personality of the product. It meets the development requirements of modern cities and is suitable for burying in the range of 2-18M. The construction of the modified MPP power cable sheath using trenchless technology not only ensures the reliability of the pipe network, reduces the failure rate of the pipe network, but also greatly improves the city appearance and environment.

-

LFT/CFP/FRP/CFRT Continuous Fiber Reinforced

Continuous fiber reinforced composite material is made of reinforced fiber material: glass fiber(GF), carbon fiber(CF), aramid fiber(AF), ultra high molecular polyethylene fiber(UHMW-PE), basalt fiber(BF) by using special process technology to makes high strength continuous fiber and thermal plastic&thermosetting resin soak with each other.