Professional Design Extrusion Film Process - PP Honeycomb Board Extrusion Line – JWELL

Professional Design Extrusion Film Process - PP Honeycomb Board Extrusion Line – JWELL Detail:

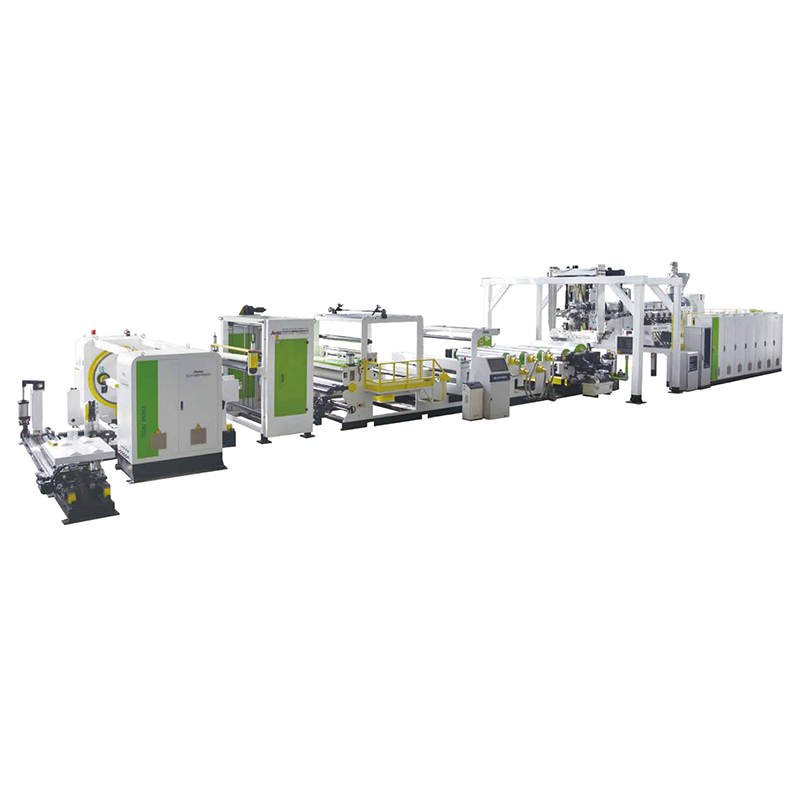

Product Presentation

PP honeycomb board through extrusion method made three layers sandwich board of one time forming, two sides is thin surface, middle is honeycomb structure; According to honeycomb structure can divide into single layer, double layer board. PP honeycomb board also can one time forming, coat fabric at two sides, leather, with light weight and high strength, non-toxic, environment, shake absorption and cold-resistant, soundproof& heat preservation, moistureproof& heat insulation etc.

Main technical parameter

| Mode | Suitable material | Products width(mm) | Products thickness(mm) | Capacity(kg/h |

| JWS75/75/75 | PP | 1200-1600 | 2-12 | 350-450 |

| JWS100/100/100 | PP | 1200-2000 | 2-20 | 600-700 |

Product detail pictures:

Related Product Guide:

Now we have superior devices. Our solutions are exported to your USA, the UK and so on, enjoying a superb name between customers for Professional Design Extrusion Film Process - PP Honeycomb Board Extrusion Line – JWELL , The product will supply to all over the world, such as: Bhutan, Bangladesh, Istanbul, If you give us a list of merchandise you are interested in, along with makes and models, we can send you quotations. Remember to email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!

Write your message here and send it to us