Renewable Design for Plastic Sheet Extrusion Process - PE Breathable Film Extrusion Line – JWELL

Renewable Design for Plastic Sheet Extrusion Process - PE Breathable Film Extrusion Line – JWELL Detail:

Product Presentation

The production line use PE air-permeable plastic granuels as raw material, and uses extrusion casting method to melt-extrude the PE-modified air-permeable plastic granuels containing inorganic filler through a flat die and the roller is stretched at a high rate to produce a sub-nanometer micro Porous membrane.

Main technical parameter

| Mode

JW130 |

Screw Diameter

130mm |

Materia

PE |

Products width

1600mm |

Capacity(Max.) 450-600kg/h | Main motor power

160KW |

| JW160 | 130mm | PE | 2200mm | 450-600kg/h | 200KW |

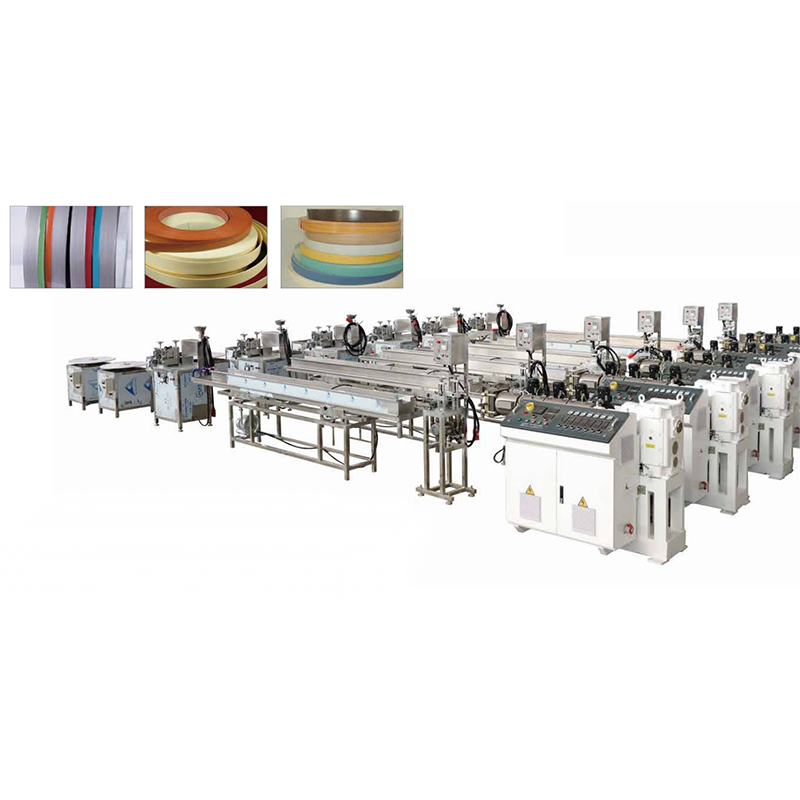

Product detail pictures:

Related Product Guide:

Sticking for the perception of Creating goods of high quality and making good friends with people today from all around the world, we constantly set the interest of shoppers to begin with for Renewable Design for Plastic Sheet Extrusion Process - PE Breathable Film Extrusion Line – JWELL , The product will supply to all over the world, such as: Zurich, Czech republic, Tunisia, All our products are exported to clients in the UK, Germany, France, Spain, the USA, Canada, Iran, Iraq, the Middle East and Africa. Our products are well welcomed by our customers for the high quality, competitive prices and the most favorable styles. We hope to establish business relationship with all customers and bring more beautifu colors for the life.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.

Write your message here and send it to us